External pressure metal E-type sealing ring (E-type outer opening)

Product Description

Metal E-ring seals are an important part of engines and are mainly used in aerospace, steam turbine and automotive industries.

"Compared with O-shaped, C-shaped, U-shaped and other metal sealing rings, its advantages lie in the small compression load required for installation, good resilience (close to 100% rebound at room temperature), and can be used under high temperature, high pressure and vibration. It is used in the working environment. During use, the E-type inner opening is suitable for internal pressure conditions, and the E-type outer opening is suitable for external pressure conditions. "The system pressure increases the adhesion between the sealing surface and the flange (self- tight function), thereby greatly reducing the leakage rate.

Specification

| Seal material selection | Incone[X-750,Inconel718, Customizable material | |||||||||||||||||||

| Section diameter * wall thickness | See selection table, customized specifications are available | |||||||||||||||||||

| Surface coating options | Gold, silver, copper, nickel, tin, PTFE, or no plating | |||||||||||||||||||

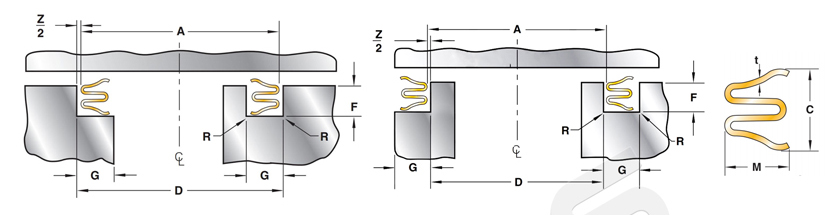

EA1 internal pressure metal E-ring

EA2 external pressure metal E-ring

Our Strengths of Metal O Ring/bag Buckle

1.We are manufacturer and trading company of Metal O Ring/bag Buckle.

2.We can provide you a wide range of Metal O Ring/bag Buckle.

3.International Certification year gold supplier.

4.Our Metal O Ring/bag Buckle has best quality and best service as well as competitive price.

5.Our Metal O Ring/bag Buckle has been ISO9001 approved.

Basic Information of Metal O Ring

1. Size: OD*ID*Thickness

2. Material: Stainless steel 304

3. Colour: Grey White

4. Temperature: About -195~+550 °C

5. Hardness: About 130~180 HB

5. Pressure: ≤30 kg/cm

6. Structure: sealing structure design of hollow metal o ring.

7. Features: 1)sealing properties; 2)high temperature and high pressure.

8. Application: Used in aerospace machinery, vacuum equipment, hydraulic machines and other mechanical equipment.

EA2 Selection Table

| OD/ID range | Nominal height | Groove depth F | Tolerance | Groove width G | E ring height C | Tolerance | E ring thickness t | E ring size M | ||||||||||||

| 45-205 | 1.6 | 1.60 | ±0.02 | 2.30 | 1.90 | ±0.08 | 0.15 | 1.70 | ||||||||||||

| 50-305 | 2.4 | 2.20 | ±0.03 | 2.90 | 2.60 | ±0.13 | 0.30 | 2.30 | ||||||||||||

| 50-305 | 2.4 | 2.20 | ±0.03 | 4.30 | 2.75 | ±0.13 | 0.30 | 3.70 | ||||||||||||

| 50-600 | 3.2 | 3.0 | ±0.05 | 4.20 | 3.35 | ±0.13 | 0.40 | 3.10 | ||||||||||||

| 85-915 | 4.80 | 4.6 | ±0.05 | 5.85 | 5.55 | ±0.15 | 0.40 | 4.80 | ||||||||||||

| 150-1220 | 6.40 | 6.28 | ±0.07 | 8.0 | 7.50 | ±0.18 | 0.50 | 6.80 | ||||||||||||