BA Blue Rubber Seal Hydraulic Rod Compact Seal

♠Beskriuwing-BA Symmetryske sealen

Hydraulyske silinder PARKER BA PU Piston stang Seal

BA Piston Rod Seal wurdt brûkt om seal de skacht, dy't kombinearret de foardielen fan BA en BS en foeget in stypjende ring.De sealing materiaal is ymportearre TPU en CPU, dat is resistint foar corrosie, hege temperatuer, hege druk en wear.

Application Range

| Druk [MPa] | Temperatuer [℃] | Skuifsnelheid[m/s] | Medium | ||||||||||

| Standert Design | 35 | -35...+80 | 0.5 | Hydraulike oaljes (basearre op minerale oalje) | |||||||||

♣ Foardiel

● Benammen sterke wear ferset.

● Unsensitiviteit foar skoklasten en drukpieken.

● Hege crush ferset.

● It hat in ideaal sealing effekt ûnder gjin lading en lege temperatuer betingsten.

● Geskikt foar easken arbeidsomstannichheden.

● Maklik te ynstallearjen.

Materiaal

| Standert Design | PU/NBR | |||||

| Spesjaal (op oanfraach) | FKM/NBR | |||||

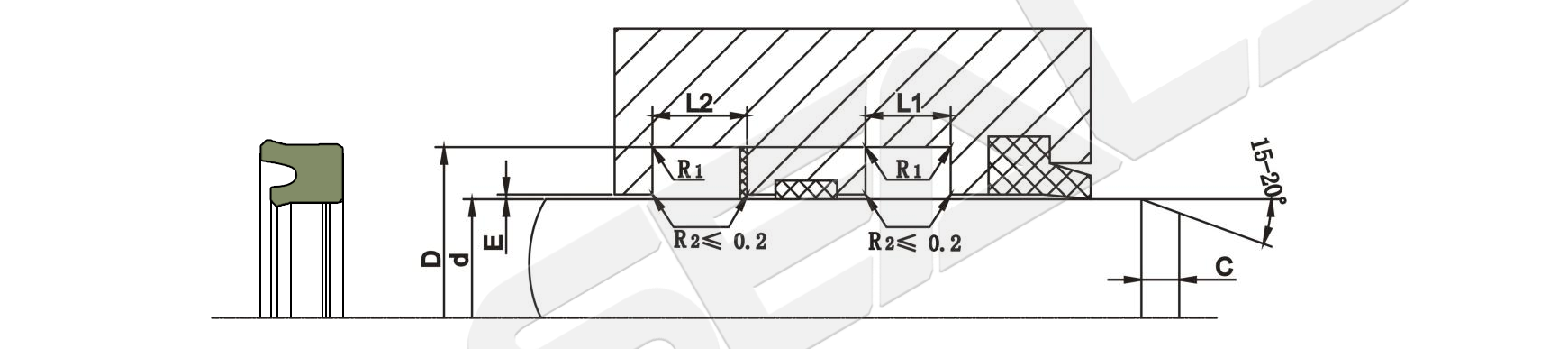

Spesifikaasje en Groove Grutte BA

| Spesifikaasje | Groove grutte | ||||

| dh9/f8 | DH10 | H | HA+03 | ||

| 3-8,5-4 | 3 | 8.5 | 4 | 4.4 | |

| 4.7-11-5 | 4.7 | 11 | 5 | 5.5 | |

| 4.8-11.1-6.4 | 4.8 | 11.1 | 6.4 | 7 | |

| 6-14-5.7 | 6 | 14 | 5.7 | 6.3 | |

| 6.35-12.7-3.18 | 6.35 | 12.7 | 3.18 | 3.7 | |

| 6.4-12.7-6.4 | 6.4 | 12.7 | 6.4 | 7 | |

| 7.9-14.3-6.4 | 7.9 | 14.3 | 6.4 | 7 | |

| 8-16-5.7 | 8 | 16 | 5.7 | 6.3 | |

| 9.53-15.88-6.35 | 9.53 | 15.88 | 6.35 | 7 | |

| 10-18-5.7 | 10 | 18 | 5.7 | 6.3 | |

| 10-20-7.3 | 10 | 20 | 7.3 | 8 | |

| 11.1-17.5-6.4 | 11.1 | 17.5 | 6.4 | 7 | |

| 12-20-5.7 | 12 | 20 | 5.7 | 6.3 | |

| 12-22-7.3 | 12 | 22 | 7.3 | 8 | |

| 12.7-19.05-4.5 | 12.7 | 19.05 | 4.5 | 5 | |

| 12.7-19.05-4.76 | 12.7 | 19.05 | 4.76 | 5.3 | |

| 12.7-19.05-6.35 | 12.7 | 19.05 | 6.35 | 7 | |

| 12.7-19.1-6.4 | 12.7 | 19.1 | 6.4 | 1 | |

| 12.7-25.4-9.5 | 12.7 | 25.4 | 9.5 | 10.5 | |

| 13-19-4 | 13 | 19 | 4 | 4.4 | |

| 13-20-5 | 13 | 20 | 5 | 5.5 | |

| 13-23-7.3 | 13 | 23 | 7.3 | 8 | |

| 14-22-5.7 | 14 | 22 | 5.7 | 6.3 | |

| 14-24-7.3 | 14 | 24 | 7.3 | 8 | |

| 14.3-20.6-6.4 | 14.3 | 20.6 | 6.4 | 7 | |

| 15-23-5.7 | 15 | 23 | 5.7 | 6.3 | |

| 15.88-22.23-3.18 | 15.88 | 22.23 | 3.18 | 3.7 | |

| 15.9-22.2-4.8 | 15.9 | 22.2 | 4.8 | 5.3 | |

| 15.9-22.2-6.4 | 15.9 | 22.2 | 6.4 | 7 | |

| 16-22.2-4.5 | 16 | 22.2 | 4.5 | 5 | |

| 16-24-5 | 16 | 24 | 5 | 5.5 | |

| 16-24-5.7 | 16 | 24 | 5.7 | 6.3 | |

| 16-25-8 | 16 | 25 | 8 | 8.8 | |

| Spesifikaasje | Groove grutte | ||||

| dh9/f8 | DH10 | H | HA+0,3 | ||

| 16-26-7.3 | 16 | 26 | 7.3 | 8 | |

| 17.5-33.3-12.7 | 17.5 | 33.3 | 12.7 | 14 | |

| 18-24-5 | 18 | 24 | 5 | 5.5 | |

| 18-26-5 | 18 | 26 | 5 | 5.5 | |

| 18-26-5.7 | 18 | 26 | 5.7 | 6.3 | |

| 18-28-7.3 | 18 | 28 | 7.3 | 8 | |

| 19-25.4-3.35 | 19 | 25.4 | 3.35 | 3.8 | |

| 19-29-7.3 | 19 | 29 | 7.3 | 8 | |

| 19.05-25.4-3.18 | 19.05 | 25.4 | 3.18 | 3.7 | |

| 19.05-25.4-4.76 | 19.05 | 25.4 | 4.76 | 5.3 | |

| 19.05-25.4-6.35 | 19.05 | 25.4 | 6.35 | 7 | |

| 19.05-31.75-6.25 | 19.05 | 31.75 | 6.25 | 6.9 | |

| 19.1-25.4-4.5 | 19.1 | 25.4 | 4.5 | 5 | |

| 19.1-25.4-6.4 | 19.1 | 25.4 | 6.4 | 1 | |

| 19.1-28.6-7.9 | 19.1 | 28.6 | 7.9 | 8.7 | |

| 20-28-5.5 | 20 | 28 | 5.5 | 6 | |

| 20-28-5.7 | 20 | 28 | 5.7 | 6.3 | |

| 20-28-6.5 | 20 | 28 | 6.5 | 7.2 | |

| 20-30-7.3 | 20 | 30 | 7.3 | 8 | |

| 20-32.7-9.5 | 20 | 32.7 | 9.5 | 10.5 | |

| 20.6-26.8-4.8 | 20.6 | 26.8 | 4.8 | 5.3 | |

| 22-30-5.7 | 22 | 30 | 5.7 | 6.3 | |

| 22-32-7.3 | 22 | 32 | 7.3 | 8 | |

| 22-35-10 | 22 | 35 | 10 | 11 | |

| 22,2-28,6-6,4 | 22.2 | 28.6 | 6.4 | 7 | |

| 22.2-31.8-7.9 | 22.2 | 31.8 | 7.9 | 8.7 | |

| 22.23-28.56-6.35 | 22.23 | 28.56 | 6.35 | 7 | |

| 24-30-5 | 24 | 30 | 5 | 5.5 | |

| 24-32-7 | 24 | 32 | 7 | 7.7 | |

| 24-35-5.7 | 24 | 35 | 5.7 | 6.3 | |

| 25-33-5.7 | 25 | 33 | 5.7 | 6.3 | |

| 25-35-7 | 25 | 35 | 7 | 7.7 | |

| 25-35-7.3 | 25 | 35 | 7.3 | 8 | |

Skriuw jo berjocht hjir en stjoer it nei ús