U1 Piston Seal Hydraulic oils (minerale oalje-basearre)

♠ Beskriuwing-U1 Piston Seal

U1 Piston Seal is in soarte fan lip seal brûkt foar it ynstallearjen piston yn 'e groove.It materiaal brûkt wurdt ymportearre CPU.Oare PU ferhâlding op 'e merk fan dit produkt, de wichtichste foardielen binne waarmte ferset, lytse kompresje deformation, wear ferset, maklik te ynstallearjen, oanpasse oan hurde arbeidsomstannichheden.

Application Range

| Druk [MPa] | Temperatuer [℃] | Skuifsnelheid[m/s] | Medium | |||||||||||||||

| Standert | 40 | -35...+100 | 0.5 | Hydraulike oaljes (basearre op minerale oalje) | ||||||||||||||

♣ Foardiel

● Benammen sterke wear ferset.

● Unsensitiviteit foar skoklasten en drukpieken.

● Hege crush ferset.

● It hat in ideaal sealing effekt ûnder gjin lading en lege temperatuer betingsten.

● Geskikt foar easken arbeidsomstannichheden.

● Maklik te ynstallearjen.

Materiaal

| Standert Design | PU | ||||||

| Spesjaal (op oanfraach) | FKM | ||||||

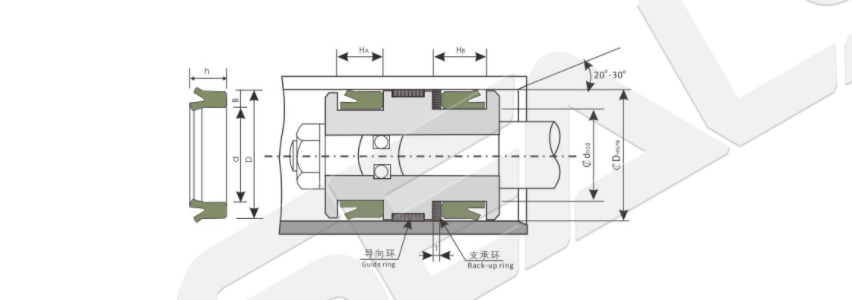

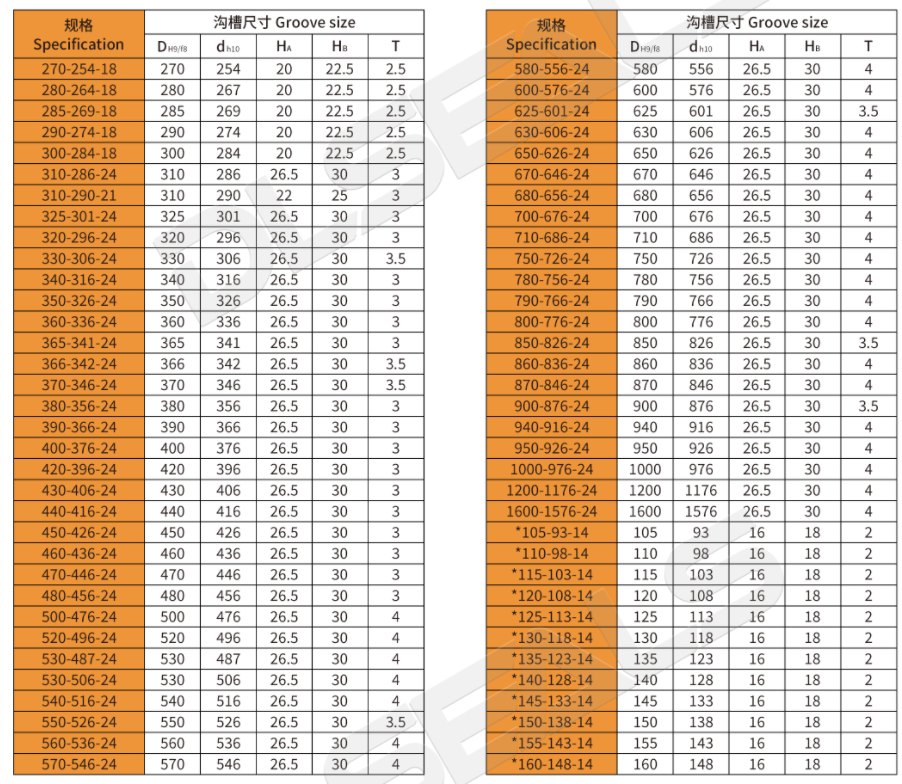

Grutte en Groove Ofmjittings U1

| Spesifikaasje | Groove grutte | ||||||||

| DH₉/f₈ | dhio | Ha | HB | T | |||||

| 11-5-8 | 11 | 5 | 9 | 10.5 | 1.5 | ||||

| 12-6-8 | 12 | 6 | 9 | 10.5 | 1.5 | ||||

| 14-8-8 | 14 | 8 | 9 | 10.5 | 1.5 | ||||

| 16-10-8 | 16 | 10 | 9 | 10.5 | 1.5 | ||||

| 18-12-8 | 18 | 12 | 9 | 10.5 | 1.5 | ||||

| 20-14-8 | 20 | 14 | 9 | 10.5 | 1.5 | ||||

| 22-16-8 | 22 | 16 | 9 | 10.5 | 1.5 | ||||

| 24-18-8 | 24 | 18 | 9 | 10.5 | 1.5 | ||||

| 25-19-8 | 25 | 19 | 9 | 10.5 | 1.5 | ||||

| 27-21-8 | 27 | 21 | 9 | 10.5 | 1.5 | ||||

| 28-22-8 | 28 | 22 | 9 | 10.5 | 1.5 | ||||

| 30-22-10 | 30 | 22 | 12 | 13.5 | 1.5 | ||||

| 32-24-10 | 32 | 24 | 12 | 13.5 | 1.5 | ||||

| 35-27-10 | 35 | 27 | 12 | 13.5 | 1.5 | ||||

| 36-28-10 | 36 | 28 | 12 | 13.5 | 1.5 | ||||

| 40-32-10 | 40 | 32 | 12 | 13.5 | 1.5 | ||||

| 43-35-10 | 43 | 35 | 12 | 13.5 | 1.5 | ||||

| 45-37-10 | 45 | 37 | 12 | 13.5 | 1.5 | ||||

| 50-42-10 | 50 | 42 | 12 | 13.5 | 1.5 | ||||

| 55-43-14 | 55 | 43 | 16 | 18 | 2 | ||||

| 55-47-10 | 55 | 47 | 12 | 13.5 | 1.5 | ||||

| 56-44-14 | 56 | 44 | 16 | 18 | 2 | ||||

| 56-48-14 | 56 | 48 | 12 | 13.5 | 2 | ||||

| 60-48-14 | 60 | 48 | 16 | 18 | 2 | ||||

| 63-51-14 | 63 | 51 | 16 | 18 | 2 | ||||

| 65-53-14 | 65 | 53 | 16 | 18 | 2 | ||||

| 68-56-14 | 68 | 56 | 16 | 18 | 2 | ||||

| 70-58-14 | 70 | 58 | 16 | 18 | 2 | ||||

| 75-63-14 | 75 | 63 | 16 | 18 | 2 | ||||

| 78-66-14 | 78 | 66 | 16 | 18 | 2 | ||||

| 80-68-14 | 80 | 68 | 16 | 18 | 2 | ||||

| 85-73-14 | 85 | 73 | 16 | 18 | 2 | ||||

| 90-78-14 | 90 | 78 | 16 | 18 | 2 | ||||

| 95-83-14 | 95 | 83 | 16 | 18 | 2 | ||||

| Spesifikaasje | Groove grutte | |||||

| DH₉/f₈ | dhio | HA | HB | T | ||

| 100-88-14 | 100 | 88 | 16 | 18 | 2 | |

| 105-89-18 | 105 | 89 | 20 | 22.5 | 2.5 | |

| 110-90-16 | 110 | 90 | 18 | 20 | 2 | |

| 110-94-18 | 110 | 94 | 20 | 22.5 | 2.5 | |

| 115-99-18 | 115 | 99 | 20 | 22.5 | 2.5 | |

| 120-104-18 | 120 | 104 | 20 | 22.5 | 2.5 | |

| 125-109-18 | 125 | 109 | 20 | 22.5 | 2.5 | |

| 127-111-18 | 127 | 111 | 20 | 22.5 | 2.5 | |

| 130-114-18 | 130 | 114 | 20 | 22.5 | 2.5 | |

| 135-119-18 | 135 | 119 | 20 | 22.5 | 2.5 | |

| 140-124-18 | 140 | 124 | 20 | 22.5 | 2.5 | |

| 145-129-18 | 145 | 129 | 20 | 22.5 | 2.5 | |

| 150-134-18 | 150 | 134 | 20 | 22.5 | 2.5 | |

| 155-139-18 | 155 | 139 | 20 | 22.5 | 2.5 | |

| 160-144-18 | 160 | 144 | 20 | 22.5 | 2.5 | |

| 165-149-18 | 165 | 149 | 20 | 22.5 | 2.5 | |

| 170-154-18 | 170 | 154 | 20 | 22.5 | 2.5 | |

| 175-159-18 | 175 | 159 | 20 | 22.5 | 2.5 | |

| 180-164-18 | 180 | 164 | 20 | 22.5 | 2.5 | |

| 185-169-18 | 185 | 169 | 20 | 22.5 | 2.5 | |

| 190-174-18 | 190 | 174 | 20 | 22.5 | 2.5 | |

| 195-179-18 | 195 | 179 | 20 | 22.5 | 2.5 | |

| 200-184-18 | 200 | 184 | 20 | 22.5 | 2.5 | |

| 210-194-18 | 210 | 194 | 20 | 22.5 | 2.5 | |

| 215-199-18 | 215 | 199 | 20 | 22.5 | 2.5 | |

| 220-204-18 | 220 | 204 | 20 | 22.5 | 2.5 | |

| 225-209-18 | 225 | 209 | 20 | 22.5 | 2.5 | |

| 230-214-18 | 230 | 214 | 20 | 22.5 | 2.5 | |

| 240-224-18 | 240 | 224 | 20 | 22.5 | 2.5 | |

| 245-229-18 | 245 | 229 | 20 | 22.5 | 2.5 | |

| 250-234-18 | 250 | 234 | 20 | 22.5 | 2.5 | |

| 255-239-18 | 255 | 139 | 20 | 22.5 | 2.5 | |

| 260-244-18 | 260 | 244 | 20 | 22.5 | 2.5 | |

| 265-249-18 | 265 | 249 | 20 | 22.5 | 2.5 | |

Skriuw jo berjocht hjir en stjoer it nei ús