ZHM Pneumatyske Seal Pneumatyske silinder Seal

♠Beskriuwing-ZHM pneumatyske seal

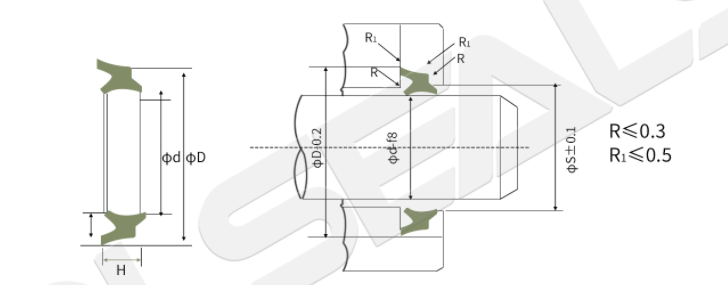

ZHM Pneumatic Seal brûkt foar reciprocating silinder stangen foar sealing en stof proofing, de measte fan dy brûke FKM / VITON en siliconenkit materiaal.De dikke sealing lip is spesifyk ûntworpen foar reciprocating silinder rod sealing applikaasjes.Neist, de sealing oriïntaasje fan in pneumatyske seal kin ynterne wêze as mei in stangsegel, ekstern as mei in piston, symmetrysk as axiaal.Mei ynterne pneumatyske seehûnen omgiet in húsfesting de seal en de sealinglip rekket de skacht.Dêrneist fereasket dizze seal hiel lyts lubricant.

Application Range

| Druk[MPa] | Temperatuer [℃] | Skuifsnelheid[m/s] | Medium | ||||||||

| Standert | 1 | -20...+200 | 1 | Komprimearre loft | |||||||

♣ Foardiel

● De elektryske eigenskippen, PTFE is in tige net-polar materiaal, mei ekstreem treflik dielectric eigenskippen, prominint as mear as 0 ℃, dielectric eigenskippen en hat gjin ynfloed op de frekwinsje mei temperatuer, vochtigheid en binne net ûnderwurpen oan ynfloed fan corrosive gas .PTFE folume resistivity en oerflak wjerstân is de heechste fan alle keunststoffen, sels nei langere ûnderdompeling yn wetter, it sil net falle signifikant, by 100% relative Feuchte fan 'e loft, it oerflak wjerstân bliuwt ûnferoare.Kristalliniteit fan PTFE op 50% oant 80%, de dielektrike sterkte is hast ûnôfhinklik fan 'e mjitte fan kristalliniteit, en hat de leechste dielektrike konstante.PTFE poerbêst arc ferset.

Materiaal

| Standert Design | NBR | |||

| Spesjaal (op oanfraach) | PU/FKM | |||

Bestelfoarbyld foar standertferzje:

| Bestelnûmer | d | D | t | h | S | H | B | ||||

| ZHM-8 | 8 | 14 | 7 | 9 | 11 | 8 | 3 | ||||

| ZHM-10 | 10 | 16 | 7 | 9 | 13 | 8 | 3 | ||||

| ZHM-12 | 12 | 18 | 7 | 9 | 15 | 8 | 3 | ||||

| ZHM-14 | 14 | 20 | 7 | 9 | 17 | 8 | 3 | ||||

| ZHM-15 | 15 | 21 | 7 | 9 | 18 | 8 | 3 | ||||

| ZHM-16 | 16 | 22 | 7 | 9 | 19 | 8 | 3 | ||||

| ZHM-18 | 18 | 24 | 7 | 9 | 21 | 8 | 3 | ||||

| ZHM-20 | 20 | 28 | 8 | 11 | 24 | 9 | 3 | ||||

| ZHM-22 | 22 | 30 | 8 | 11 | 26 | 9 | 3 | ||||

| ZHM-25 | 25 | 33 | 8 | 11 | 29 | 9 | 3 | ||||

| ZHM-28 | 28 | 36 | 8 | 11 | 32 | 9 | 3 | ||||

| ZHM-30 | 30 | 38 | 8 | 11 | 34 | 9 | 3 | ||||

| ZHM-32 | 32 | 40 | 8 | 11 | 36 | 9 | 3 | ||||

| ZHM-35 | 35 | 43 | 8 | 11 | 39 | 9 | 3 | ||||

| ZHM-36 | 36 | 44 | 8 | 11 | 40 | 9 | 3 | ||||

| ZHM-40 | 40 | 48 | 8 | 11 | 44 | 9 | 3 | ||||

| ZHM-45 | 45 | 57 | 11 | 15 | 50 | 12 | 3.5 | ||||

| ZHM-45 | 45 | 58 | 11 | 15 | 50 | 12 | 3.5 | ||||

| ZHM-50 | 50 | 62 | 11 | 15 | 55 | 12 | 3.5 | ||||

| ZHM-55 | 55 | 67 | 11 | 15 | 60 | 12 | 3.5 | ||||

| ZHM-60 | 60 | 72 | 11 | 15 | 65 | 12 | 3.5 | ||||

| ZHM-63 | 63 | 75 | 11 | 15 | 68 | 12 | 3.5 | ||||

| ZHM-65 | 65 | 77 | 11 | 15 | 70 | 12 | 3.5 | ||||

| ZHM-70 | 70 | 82 | 11 | 15 | 75 | 12 | 3.5 | ||||

| ZHM-75 | 75 | 87 | 11 | 15 | 80 | 12 | 3.5 | ||||

| ZHM-80 | 80 | 92 | 11 | 15 | 85 | 12 | 3.5 | ||||

| ZHM-85 | 85 | 97 | 11 | 15 | 90 | 12 | 3.5 | ||||

| ZHM-90 | 90 | 102 | 11 | 15 | 95 | 12 | 3.5 | ||||

| ZHM-100 | 100 | 112 | 11 | 15 | 105 | 12 | 3.5 | ||||