Nau'in Axial Metal C-nau'in Hatimin Hatimin Ƙarfe Mai Sauƙi

Bayanin Samfura

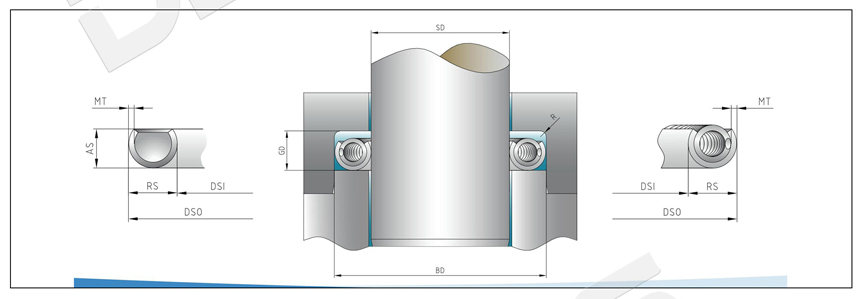

"Axial karfe C-nau'in sealing zobe ya dace da axial sealing na cylindrical sarari tsakanin rami da shaft, da sealing zobe ne tsangwama shige tare da rami da shaft bi da bi, da kuma bude shugabanci na C-type fuskantar matsakaici. gefen matsa lamba.

Bayan shigarwa, zoben C-dimbin yawa yana cikin yanayin nakasar da ta wuce kima, kuma elasticity na zoben C-dimbin yawa ya sa zoben rufewa ya dace da rami da shaft;lokacin aiki, matsakaicin matsa lamba ya cika rami na ciki mai siffar C, yana yin zoben rufewa, ramin da ramin ya dace sosai.M, don cimma hatimin damtse kai.Zoben rufewa ya dace don rufe nau'ikan matsi daban-daban da ƙananan matsa lamba da nau'ikan kafofin watsa labarai daban-daban, kuma ana iya amfani da su don rufewa mai ƙarfi na axially."

Wani marmaro (ko wani jiki na roba) yana cikin rami mai siffar C, wanda zai iya jure matsi mafi girma ko firgita da rawar jiki, kuma yana da ingantaccen abin dogaro.

Ƙayyadaddun bayanai

| Zabin kayan hatimi | Inconel718, Abubuwan da za a iya canza su | ||||||||

| Zaɓin Abubuwan Kayayyakin bazara | 321,304,316,InconelX-750,Inconel718,GH605,NINONIC90..Customizable abu | ||||||||

| Diamita na sashi * kaurin bango | Dubi teburin zaɓi, akwai takamaiman ƙayyadaddun bayanai | ||||||||

| Zaɓuɓɓukan suturar saman | Azurfa, jan karfe, nickel, ko wanda ba a rufe ba | ||||||||

Teburin Zabin Ring na nau'in Axial Metal C

| SD | RS | MT | AS | DSO | DSl | BD | SD | |||

| 9-32 | 1.6 | 0.25 | 0.35 | 1.3 | BD+0.08 | ± 0.03 | SD-0.08 | ± 0.03 | (-0.03,0) | (0, +0.03) |

| 32-64 | 0.25 | 0.35 | BD+0.10 | ± 0.03 | SD-0.10 | ± 0.03 | (-0.03,0) | (0, +0.03) | ||

| 12-32 | 2.4 | 0.25 | 0.4 | 2.05 | BD+0.08 | ± 0.03 | SD-0.08 | ± 0.03 | (-0.03,0) | (0, +0.03) |

| 32-76 | 0.25 | 0.4 | BD+0.10 | ± 0.03 | SD-0.10 | ± 0.03 | (-0.03,0) | (0, +0.03) | ||

| 19-64 | 3.2 | 0.4 | 0.5 | 2.6 | BD+0.08 | ± 0.03 | SD-0.08 | ± 0.03 | (-0.03,0) | (0, +0.03) |

| 64-203 | 0.4 | 0.5 | BD+0.15 | ± 0.05 | SD-0.15 | ± 0.05 | (-0.05,0) | (0, +0.05) | ||

| 50-152 | 4 | 0.5 | 0.65 | 3.3 | BD+0.15 | ± 0.05 | SD-0.15 | ± 0.05 | (-0.05,0) | (0, +0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.18 | ± 0.05 | SD-0.18 | ± 0.05 | (-0.05,0) | (0, +0.05) | ||

| 76-152 | 4.8 | 0.5 | 0.65 | 4.1 | BD+0.18 | ± 0.05 | SD-0.18 | ± 0.05 | (-0.05,0) | (0, +0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.20 | ± 0.06 | SD-0.20 | ± 0.06 | (-0.05,0) | (0, +0.05) | ||

| 102-165 | 6.4 | 0.64 | 0.8 | 5.4 | BD+0.20 | ± 0.06 | SD-0.20 | ± 0.06 | (-0.05,0) | (0, +0.05) |

| 165-254 | 0.64 | 0.8 | BD+0.23 | ± 0.06 | SD-0.23 | ± 0.06 | (-0.05,0) | (0, +0.05) | ||

| 254-400 | 0.64 | 0.8 | BD+0.26 | ± 0.08 | SD-0.26 | ± 0.08 | (-0.05,0) | (0, +0.05) | ||

| 400-600 | 0.64 | 0.8 | BD+0.30 | ± 0.10 | SD-0.30 | ± 0.10 | (-0.05,0) | (0, +0.05) | ||