DHS Wiper Seal Nggunakake poly urethane (PU) minangka bahan

♠Deskripsi-IDU Rod Seal

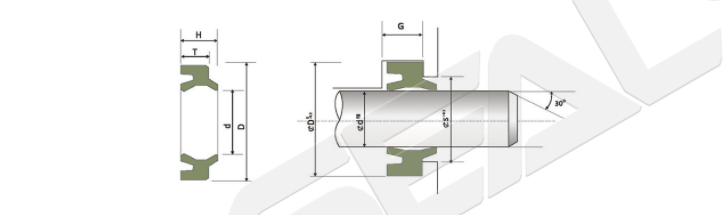

DHS minangka segel sing ngalangi bledug mlebu, nglindhungi peralatan lan njaga kinerja sealing. Nggunakake poli urethane (PU) minangka bahan, iki minangka unsur sealing tahan bledug kanggo tutuk lambe kaping pindho.

DHS Wiper Seal nduweni segel lambe kaping pindho kanthi lambe bledug lan lambe segel minyak.Struktur kasebut ndadekake banget tahan bledug lan kurang bocor lenga.Kajaba iku, Wiper lambe pindho jinis DH / DHS nyegah entri bledug, rereget, wedhi lan serpihan logam.Utamane digunakake ing silinder hidrolik lan silinder, Gerakan aksial hoist lan rod panuntun.DHS Wiper Seal kanggo nindakake gerakan piston reciprocating.

Range Aplikasi

| Tekanan [MPa] | Suhu [℃] | Kacepetan geser[m/s] | Sedheng | ||||||||||||

| Standar | 35...+100 | 1 | Minyak hidrolik (basis lenga mineral) | ||||||||||||

♣ Kaluwihan

● Insensibilitas marang beban kejut lan puncak tekanan

● resistance dhuwur marang extrusion

● Lubrication cekap amarga medium meksa antarane lambé sealing

● Cocog kanggo kahanan kerja sing paling angel

● Gampang instalasi

Bahan

| Desain Standar | PU/NBR | |||||

| Khusus (by request) | FKM/NBR | |||||

| Standard lan / utawa bisa pas alur | ||||||

| JB/ZQ 4265 | ||||||

| GY1 |

Tuladha Pesenan Kanggo Versi Standar:

| Spesifikasi | Ukuran groove | ||||||

| df⁸ | D-0.2 | S±0.1 | G+03 | ||||

| 9-14-3.5/5 | 9 | 14 | 11.6 | 4 | |||

| 10-15-3.8/6.4 | 10 | 15 | 12.6 | 4.3 | |||

| 10-20-4/8 | 10 | 20 | 15 | 4.5 | |||

| 11.2-19.2-4.5/6 | 11.2 | 19.2 | 15.5 | 5 | |||

| 12-16-3/4 | 12 | 16 | 14 | 3.5 | |||

| 12-17-3.2/4,2 | 12 | 17 | 14.6 | 3.7 | |||

| 12-18-2.5/5 | 12 | 18 | 15.3 | 3 | |||

| 12-18-3.6/4.8 | 12 | 18 | 15.3 | 4.1 | |||

| 12-18-3.8/4.8 | 12 | 18 | 15.3 | 4.3 | |||

| 12-18-3.8/6.4 | 12 | 18 | 15.3 | 4.3 | |||

| 12-18-3.9/6 | 12 | 18 | 15.3 | 4.4 | |||

| 12-20-4.5/6* | 12 | 20 | 16.3 | 5 | |||

| 12.5-20.5-4.5/6* | 12.5 | 20.5 | 16.8 | S | |||

| 13-20-5/6.5 | 13 | 20 | 16.5 | 6 | |||

| 14-22-4.5/6* | 14 | 22 | 18.3 | 5 | |||

| 16-22-3.6/4.8 | 16 | 22 | 19.3 | 4.1 | |||

| 16-22-8/10 | 16 | 22 | 19.3 | 9 | |||

| 16-24-4.5/6 | 16 | 24 | 20.3 | 5 | |||

| 16-26-7/9.5 | 16 | 26 | 21 | 8 | |||

| 18-24-3.6/4.8 | 18 | 24 | 21.3 | 4.1 | |||

| 18-26-4.5/6* | 18 | 26 | 22.3 | 5 | |||

| 18-28-4/8 | 18 | 28 | 23 | 4.5 | |||

| 18.5-26-3.214 | 18.5 | 26 | 22.8 | 3.7 | |||

| 19-27-4.5/6* | 19 | 27 | 23.3 | 5 | |||

| 19.05-29.05-5.3/7 | 19.05 | 29.05 | 24.05 | 6.3 | |||

| 20-26-3/6 | 20 | 26 | 23.3 | 3.5 | |||

| 20-26-3.6/4.8 | 20 | 26 | 23.3 | 4.1 | |||

| 20-26-3.6/5 | 20 | 26 | 23.3 | 4.1 | |||

| 20-26-6/8 | 20 | 26 | 23.3 | 7 | |||

| 20-28-4.5/6 | 20 | 28 | 24.3 | 5 | |||

| Spesifikasi | Ukuran groove | ||||

| dfs | D-0.2 | S±0.1 | G+03 | ||

| 20-28-5/6.5 | 20 | 28 | 24.3 | 6 | |

| 20-30-7/10 | 20 | 30 | 25 | 8 | |

| 20-32-5/10 | 20 | 32 | 26 | 6 | |

| 22-30-4.5/6* | 22 | 30 | 26.3 | 5 | |

| 22-33.8-2.5 / 3.5 | 22 | 33.8 | 27.9 | 3 | |

| 22.4-30.4-4.5/6* | 22.4 | 30.4 | 26.7 | 5 | |

| 23.5-31.5-4.5/6 | 23.5 | 31.5 | 27.8 | 5 | |

| 24-32-4.5/6 | 24 | 32 | 28.3 | 5 | |

| 25-30-4.5/6 | 25 | 30 | 27.6 | 5 | |

| 25-31-3.6/5 | 25 | 31 | 28.3 | 4.1 | |

| 25-31-4/6 | 25 | 31 | 28.3 | 4.5 | |

| 25-33-4.5/6 | 25 | 33 | 29.3 | 5 | |

| 25-35-5.3/ | 25 | 35 | 29.3 | 6.3 | |

| 25-36.8-5/8 | 25 | 36.8 | 31.5 | 6 | |

| 26-34-4.5/6 | 26 | 34 | 30.3 | 5 | |

| 27-35-4.5/6* | 27 | 35 | 31.3 | 5 | |

| 28-36-4.5/6* | 28 | 36 | 32.3 | 5 | |

| 28-36-47 | 28 | 36 | 32.3 | 4.5 | |

| 28-39.8-4.5/6 | 28 | 39.8 | 34.5 | 5 | |

| 28-40-5/10 | 28 | 40 | 34.5 | 6 | |

| 29-40-4.5 / 6.5 | 29 | 40 | 35 | S | |

| 30-38-4/7 | 30 | 38 | 34 | 4.5 | |

| 30-38-4.5 / 5.8 | 30 | 38 | 34 | 5 | |

| 30-38-4.5/6 | 30 | 38 | 34 | 5 | |

| 30-38-5/6.5 | 30 | 38 | 34 | 6 | |

| 30-40-5/6.5 | 30 | 40 | 35 | 6 | |

| 31.5-39.5-5 / 6.5 | 31.5 | 39.5 | 35.5 | 6 | |

| 31.75-41.28-5.5 / 7.5 | 31.75 | 41.28 | 36.75 | 6.5 | |

| 32-40-4.5 / 5.8 | 32 | 40 | 36 | 5 | |

| 32-40-5/6.5 | 32 | 40 | 36 | 6 | |