ZHM Pneumatic Seal Pneumatic Cylinder Seal

♠Deskripsi-ZHM Pneumatic Seal

ZHM Pneumatic Seal digunakake kanggo reciprocating rod silinder kanggo sealing lan proofing bledug, paling kang nggunakake FKM / VITON lan bahan silikon.Lambe sealing sing kenthel dirancang khusus kanggo aplikasi sealing rod silinder timbal balik.Kajaba iku, orientasi segel pneumatik bisa dadi internal kaya rod segel, eksternal kaya piston, simetris, utawa aksial.Kanthi segel pneumatik internal, bolongan omah ngubengi segel lan lambe sealing nyentuh poros.Kajaba iku, segel iki mbutuhake pelumas sing sithik.

Range Aplikasi

| Tekanan [MPa] | Suhu [℃] | Kacepetan geser[m/s] | Sedheng | ||||||||

| Standar | 1 | -20...+200 | 1 | Udara sing dikompres | |||||||

♣ Kaluwihan

● Sifat-sifat listrik, PTFE minangka bahan non-polar, kanthi sifat dielektrik sing apik banget, utamane nalika luwih saka 0 ℃, sifat dielektrik lan ora mengaruhi frekuensi kanthi suhu, asor lan ora kena pengaruh gas korosif .Resistivitas volume PTFE lan resistivity lumahing paling dhuwur ing kabeh plastik, sanajan sawise kecemplung ing banyu sing suwe, ora bakal ilang, ing asor relatif 100% saka udhara, resistivity lumahing tetep ora owah.Crystallinity saka PTFE ing 50% kanggo 80%, kekuatan dielektrik meh sawijining saka jurusan saka crystallinity, lan gadhah pancet dielektrik paling.PTFE resistance busur banget.

Bahan

| Desain Standar | NBR | |||

| Khusus (by request) | PU/FKM | |||

Tuladha Pesenan Kanggo Versi Standar:

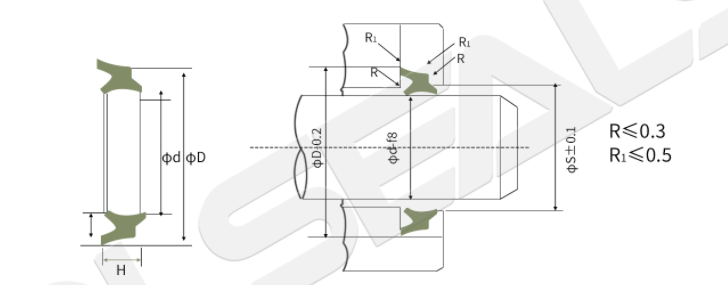

| Nomer pesenan | d | D | t | h | S | H | B | ||||

| ZHM-8 | 8 | 14 | 7 | 9 | 11 | 8 | 3 | ||||

| ZHM-10 | 10 | 16 | 7 | 9 | 13 | 8 | 3 | ||||

| ZHM-12 | 12 | 18 | 7 | 9 | 15 | 8 | 3 | ||||

| ZHM-14 | 14 | 20 | 7 | 9 | 17 | 8 | 3 | ||||

| ZHM-15 | 15 | 21 | 7 | 9 | 18 | 8 | 3 | ||||

| ZHM-16 | 16 | 22 | 7 | 9 | 19 | 8 | 3 | ||||

| ZHM-18 | 18 | 24 | 7 | 9 | 21 | 8 | 3 | ||||

| ZHM-20 | 20 | 28 | 8 | 11 | 24 | 9 | 3 | ||||

| ZHM-22 | 22 | 30 | 8 | 11 | 26 | 9 | 3 | ||||

| ZHM-25 | 25 | 33 | 8 | 11 | 29 | 9 | 3 | ||||

| ZHM-28 | 28 | 36 | 8 | 11 | 32 | 9 | 3 | ||||

| ZHM-30 | 30 | 38 | 8 | 11 | 34 | 9 | 3 | ||||

| ZHM-32 | 32 | 40 | 8 | 11 | 36 | 9 | 3 | ||||

| ZHM-35 | 35 | 43 | 8 | 11 | 39 | 9 | 3 | ||||

| ZHM-36 | 36 | 44 | 8 | 11 | 40 | 9 | 3 | ||||

| ZHM-40 | 40 | 48 | 8 | 11 | 44 | 9 | 3 | ||||

| ZHM-45 | 45 | 57 | 11 | 15 | 50 | 12 | 3.5 | ||||

| ZHM-45 | 45 | 58 | 11 | 15 | 50 | 12 | 3.5 | ||||

| ZHM-50 | 50 | 62 | 11 | 15 | 55 | 12 | 3.5 | ||||

| ZHM-55 | 55 | 67 | 11 | 15 | 60 | 12 | 3.5 | ||||

| ZHM-60 | 60 | 72 | 11 | 15 | 65 | 12 | 3.5 | ||||

| ZHM-63 | 63 | 75 | 11 | 15 | 68 | 12 | 3.5 | ||||

| ZHM-65 | 65 | 77 | 11 | 15 | 70 | 12 | 3.5 | ||||

| ZHM-70 | 70 | 82 | 11 | 15 | 75 | 12 | 3.5 | ||||

| ZHM-75 | 75 | 87 | 11 | 15 | 80 | 12 | 3.5 | ||||

| ZHM-80 | 80 | 92 | 11 | 15 | 85 | 12 | 3.5 | ||||

| ZHM-85 | 85 | 97 | 11 | 15 | 90 | 12 | 3.5 | ||||

| ZHM-90 | 90 | 102 | 11 | 15 | 95 | 12 | 3.5 | ||||

| ZHM-100 | 100 | 112 | 11 | 15 | 105 | 12 | 3.5 | ||||