Axial Metal C-type sigillum Ring Spring Metal Weatherstripping

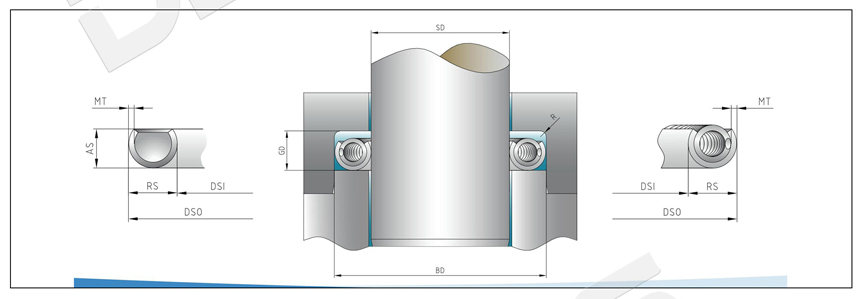

depictio producti

"Axialis metalli C-typus signandi anulus aptior est ad axialem signationem spatii cylindrici inter foveam et scapi, anulus sigillatio inter foraminis et scapi respective apta est, et directio aperturae C-typi medium respicit. pressus latus.

Post institutionem, anulus C-formatus in statu deformationis nimiae elasticae est, et elasticitas annuli C-formatorum facit annulum signaculum aptissimum cum foramine et stipite;cum operando, pressionis mediae cavitatem interiorem C-formatam implet, obsignatio anulum, foramen et scapi aptius aptius.Stricta, ut ad consequendum proprium sigillum strictum.Annulus obsignatio aptus est ad signandum varias pressuras altas et infimas et varias instrumentorum rationes, et etiam adhiberi potest ad signationem dynamicam axialiter movendam."

Fons (vel aliud corpus elasticum) in cavo interiore C informibus inseritur, quod altiorem pressionem vel concussionem et tremorem validiorem sustinere potest, et firmior signandi constantiam habet.

Specification

| Sigillum materia lectio | Inconel718, materia customizable | ||||||||

| Electio Material vere | 321、304、316、InconelX-750、Inconel718, GH605, NINONIC90..Customizable material | ||||||||

| Sectio diametri parietis crassitudine | Videre mensam delectu, nativus specificationes in promptu sunt | ||||||||

| Superficiem coating optiones | Argentum, aes, nickel, vel patula | ||||||||

Axial Metal C-type Sigillum Ring Electio Table

| SD | RS | MT | AS | DSO | DSl | BD | SD | |||

| 9-32 | 1.6 | 0.25 | 0.35 | 1.3 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0,+0.03) |

| 32-64 | 0.25 | 0.35 | BD+0.10 | ±0.03 | SD-0.10 | ±0.03 | (-0.03,0) | (0,+0.03) | ||

| 12-32 | 2.4 | 0.25 | 0.4 | 2.05 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0,+0.03) |

| 32-76 | 0.25 | 0.4 | BD+0.10 | ±0.03 | SD-0.10 | ±0.03 | (-0.03,0) | (0,+0.03) | ||

| 19-64 | 3.2 | 0.4 | 0.5 | 2.6 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0,+0.03) |

| 64-203 | 0.4 | 0.5 | BD+0.15 | ±0.05 | SD-0.15 | ±0.05 | (-0.05,0) | (0,+0.05) | ||

| 50-152 | 4 | 0.5 | 0.65 | 3.3 | BD+0.15 | ±0.05 | SD-0.15 | ±0.05 | (-0.05,0) | (0,+0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.18 | ±0.05 | SD-0.18 | ±0.05 | (-0.05,0) | (0,+0.05) | ||

| 76-152 | 4.8 | 0.5 | 0.65 | 4.1 | BD+0.18 | ±0.05 | SD-0.18 | ±0.05 | (-0.05,0) | (0,+0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.20 | ±0.06 | SD-0.20 | ±0.06 | (-0.05,0) | (0,+0.05) | ||

| 102-165 | 6.4 | 0.64 | 0.8 | 5.4 | BD+0.20 | ±0.06 | SD-0.20 | ±0.06 | (-0.05,0) | (0,+0.05) |

| 165-254 | 0.64 | 0.8 | BD+0.23 | ±0.06 | SD-0.23 | ±0.06 | (-0.05,0) | (0,+0.05) | ||

| 254-400 | 0.64 | 0.8 | BD+0.26 | ±0.08 | SD-0.26 | ±0.08 | (-0.05,0) | (0,+0.05) | ||

| 400-600 | 0.64 | 0.8 | BD+0.30 | ±0.10 | SD-0.30 | ±0.10 | (-0.05,0) | (0,+0.05) | ||