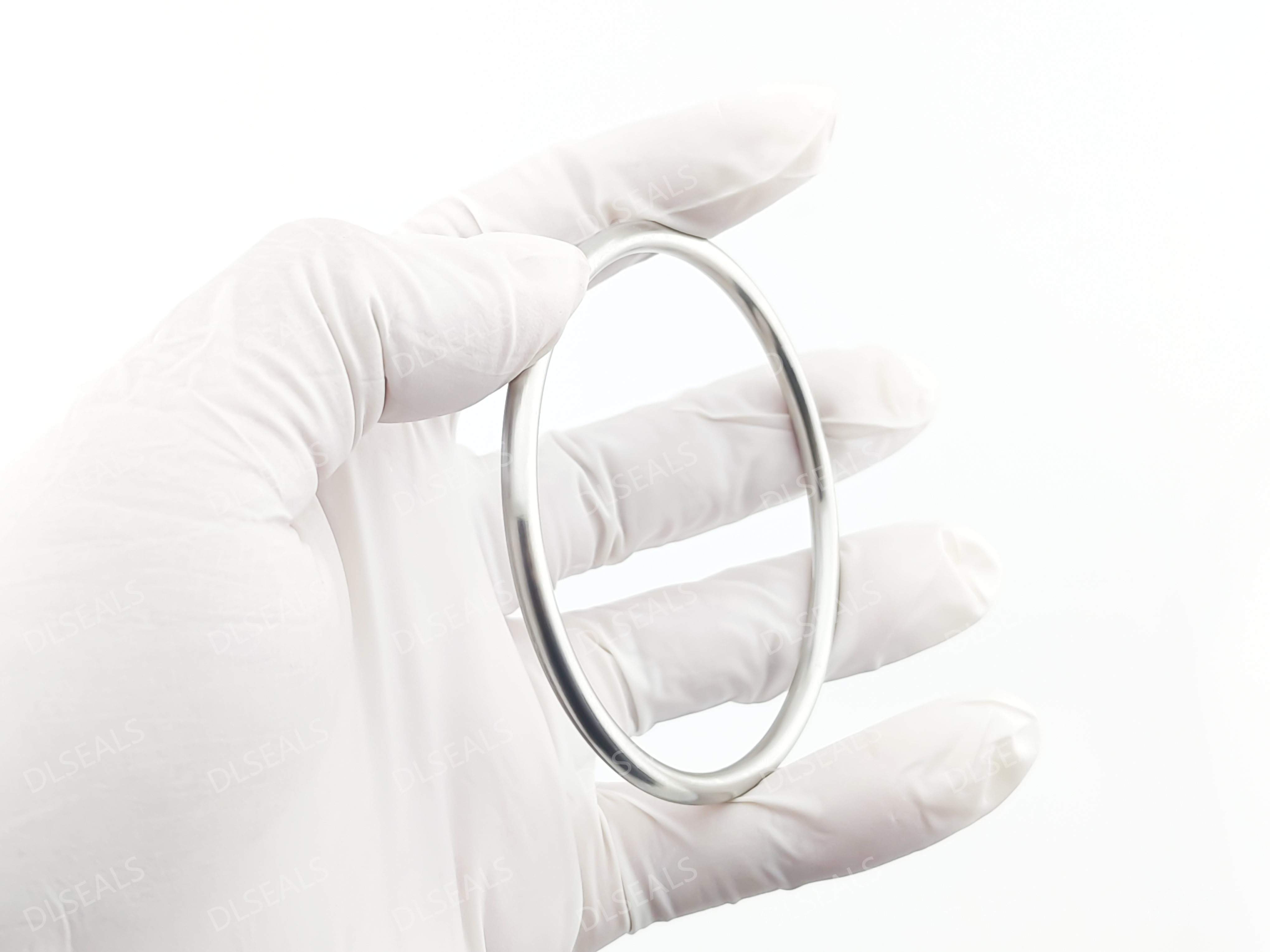

Metal O-rings play an important role in sealing and connection systems, and their performance directly affects the reliability and working efficiency of equipment. However, in order to ensure that metal O-rings do not deform during use and ensure their sealing and stability, comprehensive considerations are required from multiple aspects. The following are some key measures that can help ensure that metal O-rings maintain good performance and avoid deformation under various working conditions.

1. Choose the right material

The first step to ensure that metal O-rings do not deform is to choose the right material. Commonly used metal materials include stainless steel, aluminum alloy, copper alloy, etc. These materials have good mechanical properties and elasticity, and can maintain stable shape under stress and high temperature environments. Choosing high-strength and corrosion-resistant metal materials can help improve the stability and life of O-rings.

2. Precision processing

Processing accuracy is crucial to the performance of metal O-rings. The inner diameter, outer diameter and cross-sectional dimensions of the O-ring must be processed strictly in accordance with the design requirements. Using high-precision processing equipment and technology can ensure that the O-ring does not have dimensional errors during the manufacturing process. This helps to avoid deformation problems caused by size mismatch.

3. Correct installation

Improper operation during installation may cause metal O-rings to deform. Use special tools during installation and ensure that the O-ring is correctly placed in the designed groove. Avoid excessive pressure or uneven force to prevent the O-ring from being damaged during installation. Following the manufacturer’s installation guidelines can effectively reduce the risk of deformation caused by improper installation.

4. Size matching

Ensure that the size of the metal O-ring matches the mating part accurately. If the size of the O-ring does not match the size of the groove, it will cause poor sealing or deformation when subjected to force. Choosing an O-ring that matches the accessory exactly can ensure its stability and reliability during use.

5. Control the use environment

The performance of metal O-rings is also affected by environmental factors. Avoid using O-rings in extreme temperatures, highly corrosive environments or high pressure conditions. Extreme temperature changes and corrosive substances may cause changes in the physical properties of metal materials, which will affect the shape and function of the O-ring. Try to use O-rings within the working range specified by the design to ensure its stability.

6. Regular maintenance and inspection

Regular inspection and maintenance of metal O-rings can help detect potential problems and solve them in time. Especially when used under high load or harsh environment, regularly checking the status of O-rings and promptly dealing with possible wear or deformation problems can effectively extend the service life of O-rings.

Conclusion

Metal O-rings play a key role in many applications, and the stability of their performance is directly related to the reliability and safety of the system. By selecting suitable materials, precise processing, correct installation, ensuring size matching, controlling the use environment, and regular maintenance and inspection, metal O-rings can be effectively prevented from deforming during use. These measures not only help to ensure the sealing performance of O-rings, but also improve the overall operating efficiency and stability of the equipment.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you’d like to know, feel free to contact us directly. DLSEALS’s product experts are dedicated to serving you!

Post time: Sep-21-2024