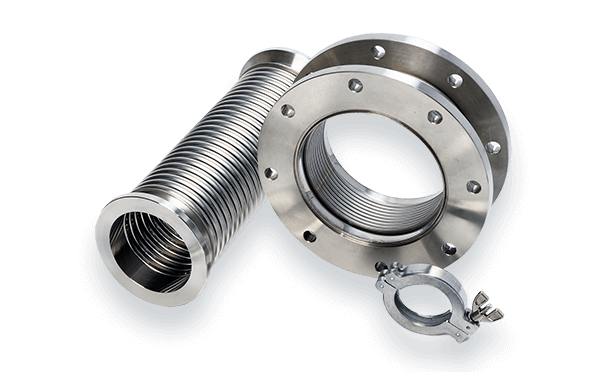

As an important engineering component, the manufacturing process of metal bellows directly affects its performance and application range. The following is a detailed introduction to the manufacturing process of metal bellows and its specific application in different application fields.

1. Manufacturing process of metal bellows

Material preparation:

Material selection: Select suitable metal materials such as stainless steel, alloy steel, titanium alloy, etc. according to the application environment and performance requirements.

Material pretreatment: Including material cutting, straightening, surface treatment (such as pickling, polishing), etc. to ensure material quality and forming performance.

Forming process:

Spin forming: By rotating and applying pressure, the metal sheet is gradually formed into a bellows. Spin forming has the advantages of high forming accuracy and high production efficiency, and is suitable for mass production.

Hydraulic forming: Use a hydraulic press to apply pressure to the metal sheet to form it into a bellows. Hydraulic forming is suitable for the manufacture of bellows with complex shapes and high precision.

Roll forming: The metal sheet is continuously extruded and rolled by rollers to form it into a bellows. Roll forming is suitable for continuous production and mass manufacturing.

Welding process:

Laser welding: Welding is performed using a high-energy laser beam, with fast welding speed and high precision, suitable for high-precision and mass production.

Argon arc welding: Welding is performed using argon protection, with stable welding quality, suitable for the manufacture of bellows made of materials such as stainless steel.

Electron beam welding: Welding is performed using an electron beam in a high vacuum environment, with a large welding depth and a small heat-affected zone, suitable for the manufacture of high-strength and high-precision bellows.

Heat treatment process:

Annealing treatment: By heating and heat preservation, the internal stress of the material is eliminated, and the toughness and ductility of the material are improved.

Tempering treatment: After annealing, tempering treatment is performed to adjust the hardness and toughness of the material and improve the fatigue life of the bellows.

Solution treatment: Suitable for stainless steel materials, through heating and rapid cooling, the alloy elements are evenly distributed, and the corrosion resistance and mechanical properties are improved.

Surface treatment:

Coating treatment: Such as galvanizing, chrome plating, etc., to improve the corrosion resistance and surface hardness of the bellows.

Coating treatment: Such as spraying high-temperature resistant or corrosion-resistant coatings, suitable for applications in special environments.

2. Application fields of metal bellows

Industrial pipelines:

Thermal expansion and contraction compensation: bellows are used to compensate for the thermal expansion and contraction of pipelines under temperature changes to prevent deformation and rupture of pipelines.

Vibration absorption: used to absorb and isolate vibrations in pipeline systems to protect pipelines and equipment from vibration damage.

Displacement absorption: used to absorb mechanical displacement in pipeline systems to maintain the stability and sealing of the system.

Aerospace:

Hydraulic system: bellows are used in the hydraulic system and fuel pipelines of aircraft engines to compensate for thermal expansion and contraction and vibration in the system.

Shock absorption system: used in the shock absorption system of aircraft landing gear and fuselage to improve the comfort and safety of aircraft.

Sealing system: used in the sealing system of aircraft to prevent gas and liquid leakage and ensure the safe operation of aircraft.

Automotive industry:

Exhaust system: bellows are used in automobile exhaust systems to compensate for thermal expansion and contraction and mechanical displacement of exhaust pipes and reduce noise and vibration.

Fuel system: used for compensation and sealing of fuel pipelines to prevent fuel leakage and system failure.

Shock absorption system: used in automobile suspension systems and engine brackets to absorb and isolate vibrations and improve the comfort and safety of vehicles.

Petrochemical industry:

High temperature and high pressure pipelines: bellows are used in high temperature and high pressure pipeline systems to compensate for the thermal expansion and contraction and mechanical displacement of pipelines to ensure the safe operation of the system.

Corrosive environment: used for pipelines and equipment in highly corrosive environments, to withstand corrosion from various chemical media, and to extend the service life of equipment.

Sealing system: used for sealing of storage tanks, reactors and valves to prevent gas and liquid leakage and ensure the safety and efficiency of the production process.

Power industry:

Boiler pipelines: bellows are used in the pipeline systems of boilers and heat exchangers to compensate for thermal expansion and contraction at high temperatures and prevent pipeline deformation and rupture.

Nuclear power plant: used in the cooling system and reactor pipelines of nuclear power plants to compensate for thermal expansion and contraction and mechanical displacement in the system to ensure the safe operation of nuclear power plants.

Sealing system: used in the sealing system of power equipment to prevent gas and liquid leakage and ensure the safe and stable operation of power equipment.

Conclusion

The manufacturing process of metal bellows is complex and diverse, involving multiple links such as material preparation, forming, welding, heat treatment and surface treatment. Through scientific and reasonable manufacturing processes, the high performance and long life of bellows can be ensured. In terms of application areas, metal bellows are widely used in industrial pipelines, aerospace, automobile industry, petrochemical industry, power industry and other fields, providing important guarantees for the safe, stable and efficient operation of various engineering systems. With the continuous development of new materials and new manufacturing technologies, the application prospects of metal bellows will be broader.

Post time: Nov-20-2024