Metal C-type seals, as a high-performance sealing component, are widely used in various industrial fields. Their main function is to prevent the leakage of liquids or gases and protect the normal operation of equipment. Due to their unique structure and excellent performance, metal C-type seals play an important role in many high-demand application scenarios. This article will explore in depth the design features, application fields and future development trends of metal C-type seals.

1. Design features of metal C-type seals

Structural features

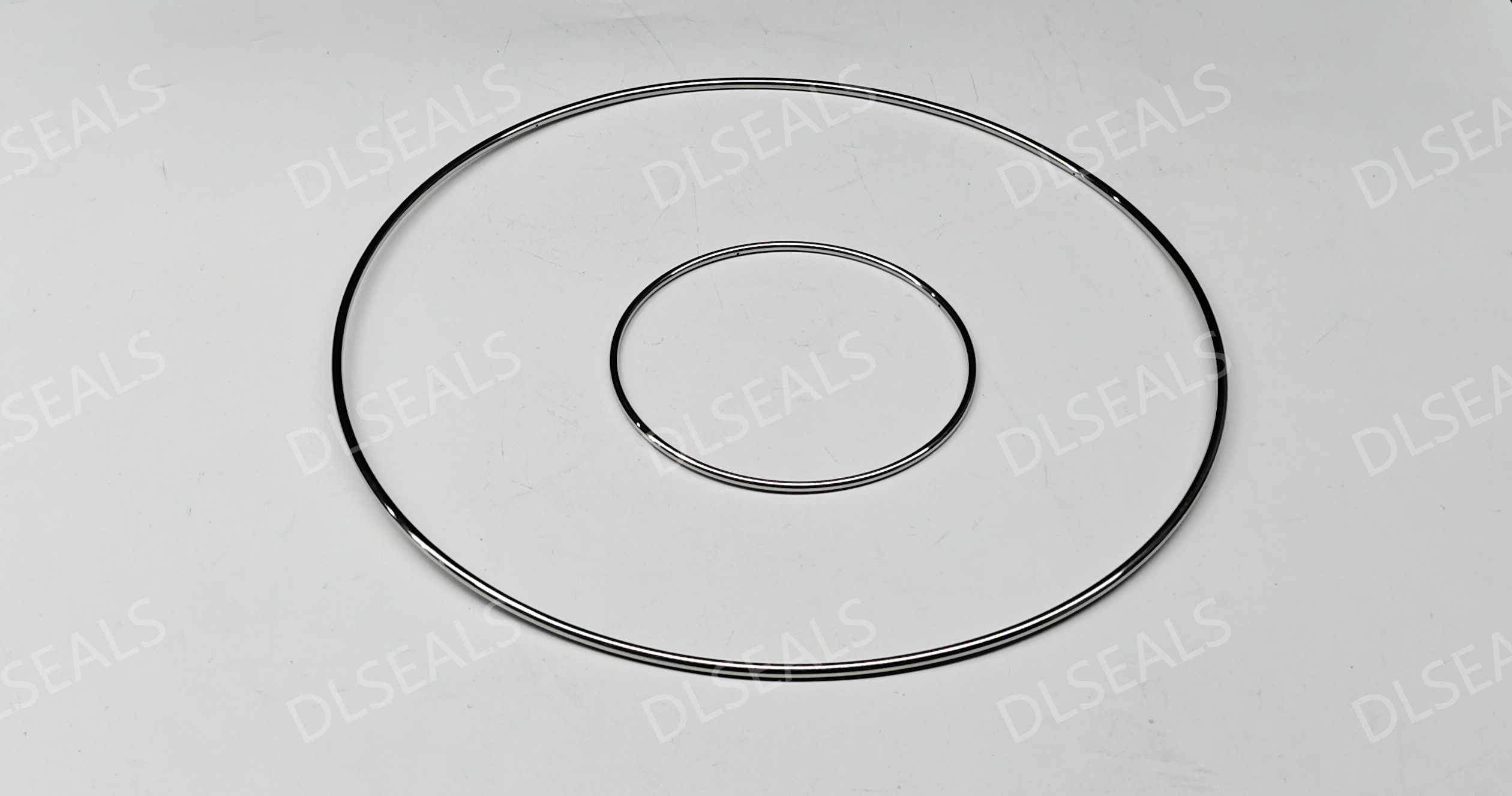

C-type cross section: The cross section of the metal C-type seal is C-shaped, which enables it to form a good compression seal effect when sealing. The C-type cross section helps to evenly distribute pressure during compression, thereby improving sealing performance.

Elasticity and strength: Metal C-type seals are usually made of high-strength metal materials (such as stainless steel or aluminum alloys), with high elasticity and strength, and can maintain stable sealing performance in extreme environments.

High temperature resistance and corrosion resistance

High temperature performance: The high temperature stability of metal materials enables metal C-type seals to work effectively in high temperature environments without deformation or performance degradation. This makes it suitable for high-temperature industrial equipment such as engines and turbines.

Corrosion resistance: Metal C-type seals can withstand the erosion of various chemical media, especially stainless steel materials with strong corrosion resistance, which can work stably in acid and alkali environments to ensure long-term use.

Installation and application

Easy installation: Metal C-type seals are usually designed as compressible seals, which can easily adapt to different fitting clearances during installation and maintain sealing performance during equipment operation.

Strong adaptability: Its design can adapt to different operating conditions and load changes, and can effectively prevent leakage and protect the normal operation of equipment.

2. Application fields of metal C-type seals

Automotive industry

Engine system: Metal C-type seals are used in automobile engines to seal high-temperature and high-pressure lubricating oil channels to prevent oil leakage and protect internal engine components.

Transmission: In the transmission, metal C-type seals are used to seal the transmission system, prevent lubricating oil leakage, and maintain the normal operation of the transmission.

Aerospace

Hydraulic system: In the hydraulic system of aerospace vehicles, metal C-type seals are used to seal high-pressure liquids to ensure the reliability and stability of the hydraulic system.

Fuel system: In the fuel system of spacecraft, metal C-type seals prevent fuel leakage and improve the safety and efficiency of the fuel system.

Industrial machinery

High temperature equipment: In high temperature industrial equipment such as boilers, turbines, etc., metal C-type seals can withstand extreme operating conditions and ensure the sealing performance of the equipment.

Chemical equipment: In chemical equipment, metal C-type seals are used to seal corrosive media and protect equipment from chemical corrosion.

Energy field

Oil and gas: In oil and gas extraction equipment, metal C-type seals are used to seal high-pressure gases and liquids to ensure the safe transportation and processing of energy.

Nuclear power equipment: In nuclear power equipment, metal C-type seals are used to seal nuclear reactors and cooling systems to prevent the leakage of radioactive materials and ensure nuclear energy safety.

3. Future trends and innovations

Material innovation

High-performance alloys: With the development of science and technology, new high-performance alloy materials (such as titanium alloys and nickel-based alloys) are being used in the production of metal C-type seals. These materials can further enhance the strength, high temperature resistance and corrosion resistance of the seals.

Composite materials: Combining metals with high-performance plastics or ceramic materials, composite metal C-type seals are developed to improve their performance under extreme conditions.

Intelligent design

Sensor integration: Future metal C-type seals may integrate sensors for real-time monitoring of sealing status and equipment operation. This intelligent design can provide real-time data to help prevent failures and perform maintenance.

Self-healing technology: Research the application of self-healing materials and develop metal C-type seals that can self-repair in the event of minor leaks or damage to improve the long-term reliability of the seal.

Manufacturing process improvement

Precision machining: Advanced precision machining technology will further improve the machining accuracy and quality of metal C-type seals, ensuring their stability and performance under various application conditions.

Environmentally friendly manufacturing: Promote the development of green manufacturing processes, reduce environmental impacts during production, and improve the environmental performance of metal C-type seals.

IV. Conclusion

Metal C-type seals play an important role in many industrial fields due to their unique design and excellent performance. Their high temperature tolerance, corrosion resistance and strength make them widely used in the automotive, aerospace, industrial machinery and energy fields. With the continuous advancement of material technology, intelligent design and manufacturing processes, the future of metal C-type seals will be full of more innovation and development opportunities, providing more reliable sealing solutions for equipment in various industries.

Post time: Sep-04-2024