1. Introduction

With the rapid development of modern industrial technology, the working environment of equipment is becoming increasingly harsh, and higher requirements are placed on sealing technology. As a high-performance sealing element, the metal E-type sealing ring can effectively solve the problem that traditional rubber sealing rings are prone to failure under extreme working conditions such as high pressure, high temperature, and strong corrosion, and provide protection for the safe and reliable operation of high-end equipment.

2. Structural characteristics of metal E-type sealing rings

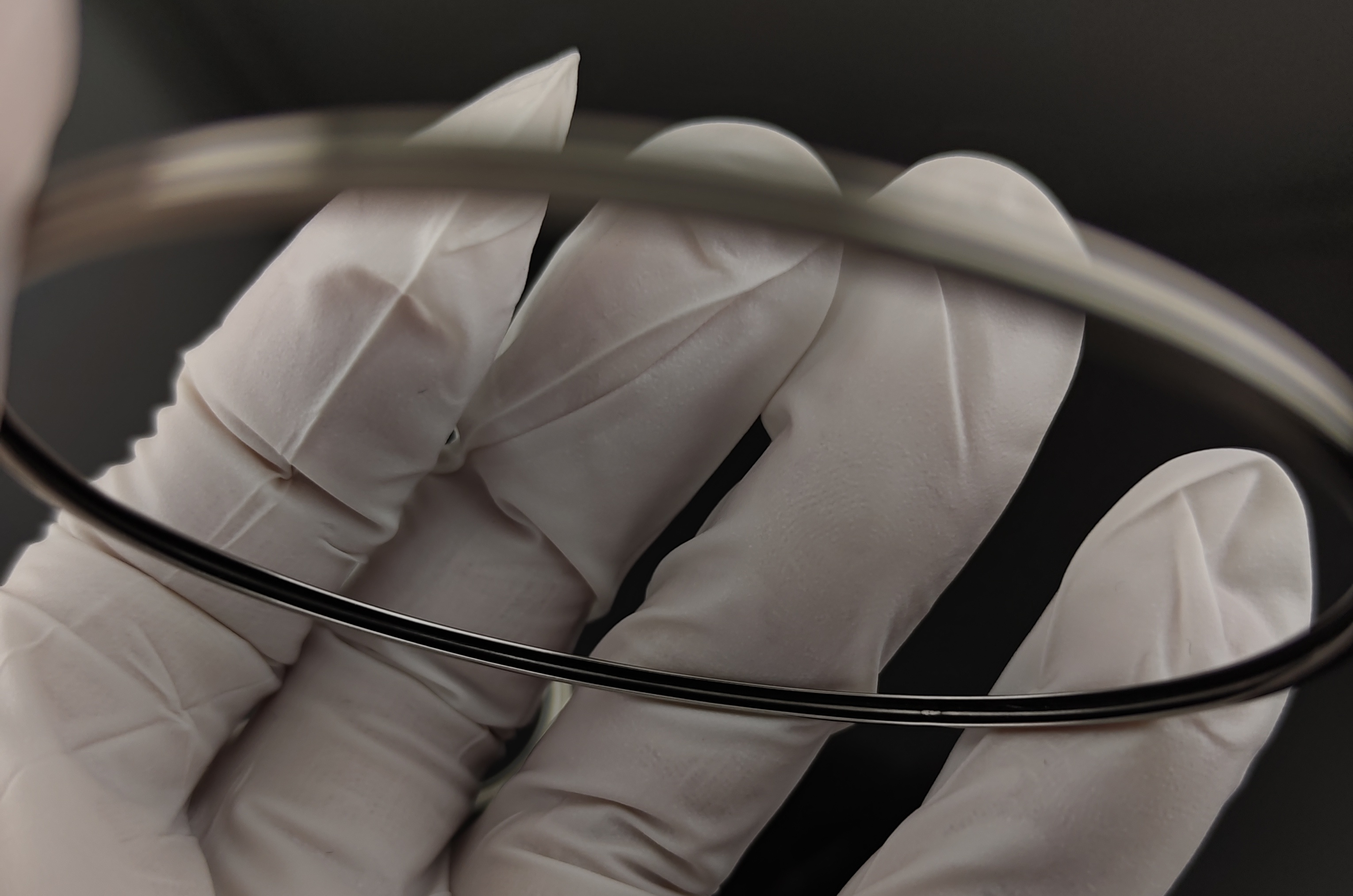

As the name suggests, the cross-sectional shape of the metal E-type sealing ring is similar to the letter “E”. This unique structural design gives it the following characteristics:

2.1 Double lip design: The E-type sealing ring has two symmetrical lips, which can achieve bidirectional sealing and effectively prevent medium leakage.

2.2 Elastic energy storage: The middle part of the E-type sealing ring is designed with an elastic energy storage groove, which can store elastic potential energy and maintain good sealing performance when pressure fluctuates.

2.3 Strong anti-extrusion ability: The cross-sectional shape and material properties of the E-type sealing ring give it a high shear strength and can effectively resist extrusion deformation under high pressure.

3. Material selection of metal E-type sealing ring

The material selection of metal E-type sealing ring is very important. It is necessary to select the appropriate material according to the specific working conditions, such as:

3.1 Stainless steel: has good corrosion resistance and mechanical properties, and commonly used grades are 304, 316, etc.

3.2 High temperature alloy: has excellent high temperature resistance, such as Inconel 718, Hastelloy C-276, etc.

3.3 Titanium alloy: has high strength, low density and good corrosion resistance, such as Ti-6Al-4V.

4. Performance advantages of metal E-type sealing ring

Compared with traditional rubber sealing rings, metal E-type sealing rings have the following significant advantages:

4.1 High pressure resistance: Metal materials have higher strength and can withstand higher pressure.

4.2 High temperature resistance: Metal materials have excellent high temperature resistance and can maintain stable sealing performance in high temperature environments.

4.3 Corrosion resistance: Selecting appropriate metal materials can effectively resist corrosion from various media.

4.4 Long life: Metal seals are not easy to age and have a long service life.

4.5 Environmentally friendly: Metal materials can be recycled and are environmentally friendly.

5. Application fields of metal E-type seals

Metal E-type seals are widely used in the following fields:

5.1 Petrochemical: High temperature and high pressure seals in oil refining and chemical equipment.

5.2 Aerospace: High temperature and high pressure seals in aircraft engines and rocket engines.

5.3 Nuclear power: High temperature and high pressure seals in nuclear power plant reactors.

5.4 Others: Shipbuilding, military industry, medical equipment and other fields.

6. Future development trend of metal E-type seals

In the future, metal E-type seals will develop in the following directions:

6.1 High-performance materials: Develop new metal materials with higher strength, high temperature resistance and corrosion resistance.

6.2 Precision manufacturing: Use advanced processing technology to improve the processing accuracy and surface quality of metal E-type seals.

6.3 Intelligence: Integrate sensors, microprocessors, etc. into metal E-type sealing rings to achieve real-time monitoring and early warning of sealing status.

6.4 Green and environmental protection: Develop recyclable and degradable environmentally friendly metal E-type sealing rings.

7. Conclusion

As a high-performance sealing element, metal E-type sealing rings have irreplaceable advantages under extreme working conditions such as high pressure, high temperature, and strong corrosion. With the continuous development of materials science, manufacturing technology, and intelligent technology, metal E-type sealing rings will play an important role in a wider range of fields and escort the safe and reliable operation of high-end equipment.

Post time: Feb-11-2025