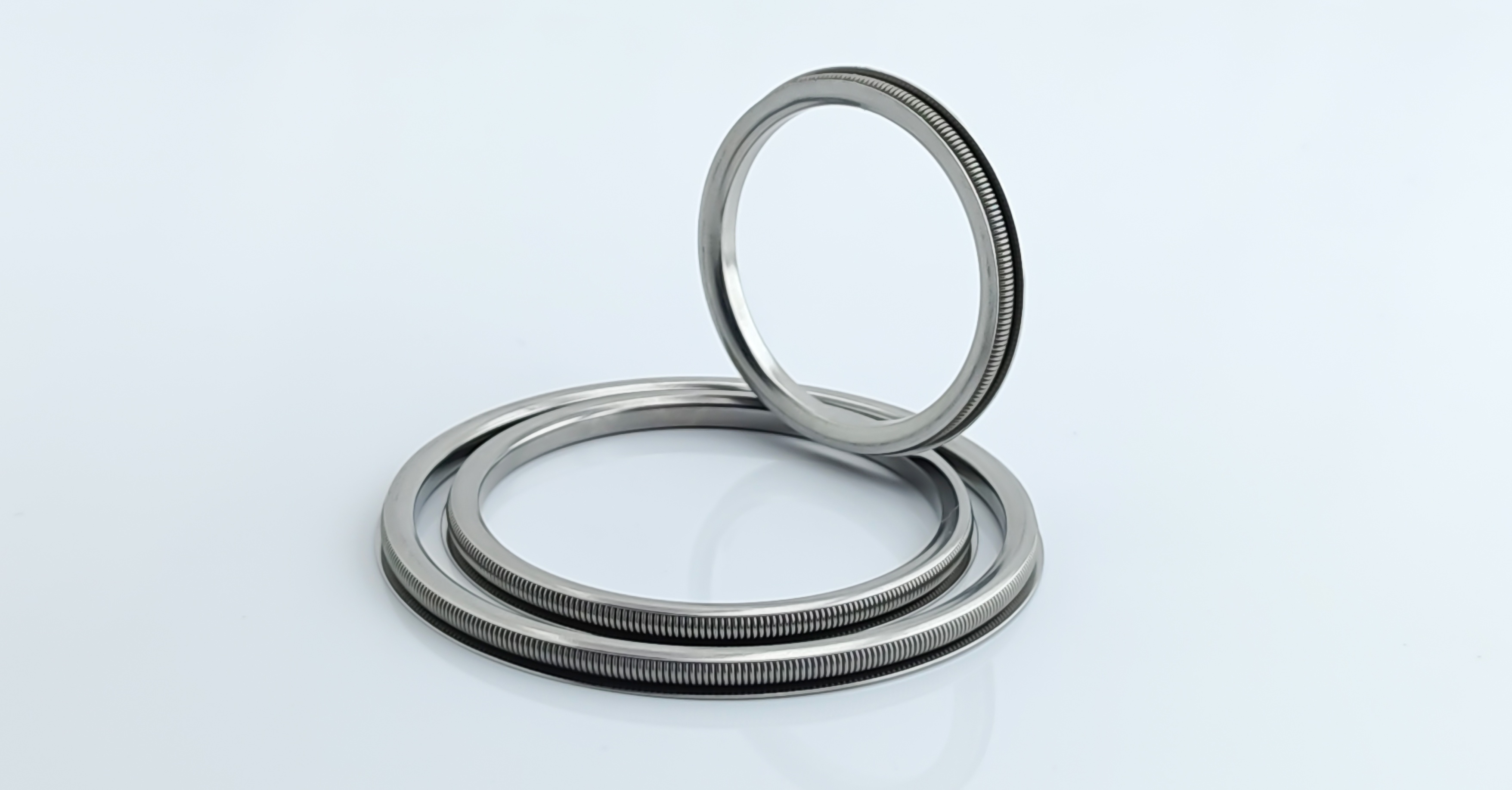

Metal sealing rings play a key role in dynamic sealing applications, and their performance directly affects the sealing effect, reliability and service life of the equipment. Dynamic sealing refers to the process of achieving sealing between moving parts, which involves the interaction between the sealing ring and the mating surface during relative motion. The following is a detailed analysis of the study of the dynamic sealing characteristics of metal sealing rings.

Metal sealing rings play a key role in dynamic sealing applications, and their performance directly affects the sealing effect, reliability and service life of the equipment. Dynamic sealing refers to the process of achieving sealing between moving parts, which involves the interaction between the sealing ring and the mating surface during relative motion. The following is a detailed analysis of the study of the dynamic sealing characteristics of metal sealing rings.

1. Basic principles of dynamic sealing

Sealing principle:

Dynamic sealing mainly relies on the contact pressure between the sealing ring and the contact surface to prevent fluid leakage.

The shape, material and installation conditions of the sealing ring directly affect the friction between the contact surfaces and the sealing ability.

Contact pressure:

During dynamic sealing, the contact pressure between the sealing ring and the mating surface is an important factor in determining the sealing performance. Appropriate contact pressure can effectively prevent medium leakage.

The contact pressure can be adjusted by optimizing the shape and material selection of the sealing ring.

2. Factors affecting dynamic sealing performance

Speed effect:

As the relative motion speed increases, the friction and heat generation between the sealing ring and the contact surface increase, which may lead to seal failure.

The formation of a lubricating film needs to be considered to reduce friction and wear and maintain sealing effectiveness.

Temperature influence:

Increased temperature may cause thermal softening, expansion or deformation of the material, affecting the working state of the sealing ring.

In high temperature environment, the mechanical strength and elastic modulus of some materials may be significantly reduced, thus affecting the sealing performance.

Medium characteristics:

The properties of the medium (such as viscosity, corrosiveness, thermal conductivity) that the sealing ring contacts directly affect the sealing effect.

Some media may cause erosion or chemical degradation to the sealing material, so it is necessary to select corresponding corrosion-resistant materials.

3. Design considerations for dynamic sealing rings

Geometric design:

The cross-sectional shape of the sealing ring (such as O-type, U-type, X-type) should be optimized according to the specific application to achieve the best sealing effect.

Appropriate radius and curvature can help improve stress distribution and contact performance.

Pressure and installation:

The compression amount should be considered during installation to ensure full contact and compression of the sealing ring during operation.

The effects of different installation methods (such as pre-pressing, elastic installation) on dynamic sealing performance also need to be experimentally verified.

4. Performance testing and evaluation

Dynamic simulation experiment:

Use dynamic testing equipment to evaluate the sealing performance and test the performance indicators such as leakage rate and friction coefficient of the sealing ring under actual working conditions.

Through cycle life test, evaluate the durability of the sealing ring under repeated movement.

Thermal analysis:

Monitor the temperature change of the sealing ring during dynamic operation and analyze the impact of different operating conditions on the sealing performance.

Use infrared thermal imager and other technologies to track temperature distribution and optimize operating conditions.

Leakage test:

Perform gas or liquid leakage test under dynamic conditions to evaluate the actual sealing performance of the sealing ring under motion.

5. Improvement measures

Lubrication technology:

Introducing lubricants or liquid films can reduce friction losses and extend the service life of the sealing ring.

Study the application effects of synthetic lubricants and solid lubricants under high temperature and high pressure.

Material innovation:

Develop new wear-resistant and high-temperature resistant materials, such as synthetic polymer composites or surface coating technology, to improve the performance of dynamic sealing rings.

Combining cutting-edge technologies such as nanomaterials to improve the performance of sealing rings.

Adaptive sealing technology:

The sealing ring designed with adaptive mechanism can automatically adjust deformation according to changes in working conditions (such as changes in temperature and pressure) to meet the requirements of dynamic sealing.

Conclusion

The study of dynamic sealing characteristics of metal sealing rings is a complex and important topic, involving multiple fields such as materials science, mechanical design, and fluid mechanics. Through in-depth understanding of the dynamic sealing principle and corresponding design optimization, the sealing performance and service life can be greatly improved, providing reliable sealing solutions for important fields such as aerospace, automobiles, chemicals, and machinery. The future development direction includes not only the optimization of existing materials and designs, but also the development of new materials and the application of intelligent sealing technology.

Post time: Nov-05-2024