♠Description-ODU PU oil seal used in hydraulic cylinder of an excavator

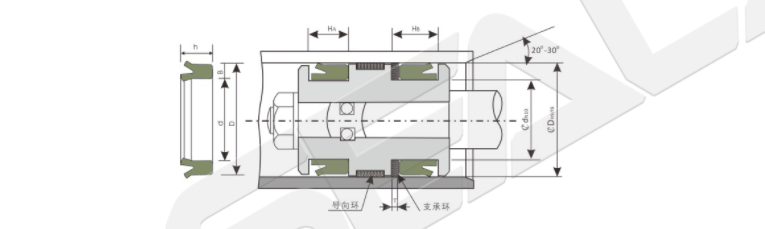

ODU Piston Seal is a kind of lip seal which is used in the groove to fit the piston. In addition, the materials are imported CPU and TPU, with a hardness of 90-95Ashore and light green color. In short, the CPU can even replace the inlet seal for harsh working conditions.

Retaining ring instructions:When using an ODU Piston Seal, there is generally no retaining ring. When the working pressure is greater than 16MPA, or because the motion pair has a large eccentricity and the gap is large. So a retaining ring is placed on the sealing ring support surface to prevent the sealing ring from being squeezed into the gap to cause early damage of the sealing ring. When the sealing ring is used for static sealing, the retaining ring can be omitted.

♥Application Range

| Pressure [MPa] | Temperature [℃] | Sliding speed[m/s] | Medium | |||||||||||||||

| Standard | 40 | -35...+200 | 0.5 | Hydraulic oils (mineral oil-based) | ||||||||||||||

♣Advantage

● Particularly strong wear resistance.

● Insensitivity to shock loads and pressure peaks.

● High crush resistance.

● It has an ideal sealing effect under no load and low-temperature conditions.

● Suitable for demanding working conditions.

● Easy to install.

♦Specification and Groove size ODU

| Specification | Groove size | ||||||||

| DH9/f8 | dh10 | Ha | HB | T | |||||

| 11-5-8 | 11 | 5 | 9 | 10.5 | 1.5 | ||||

| 12-6-8 | 12 | 6 | 9 | 10.5 | 1.5 | ||||

| 14-8-8 | 14 | 8 | 9 | 10.5 | 1.5 | ||||

| 16-10-8 | 16 | 10 | 9 | 10.5 | 1.5 | ||||

| 18-12-8 | 18 | 12 | 9 | 10.5 | 1.5 | ||||

| 20-14-8 | 20 | 14 | 9 | 10.5 | 1.5 | ||||

| 22-16-8 | 22 | 16 | 9 | 10.5 | 1.5 | ||||

| 24-18-8 | 24 | 18 | 9 | 10.5 | 1.5 | ||||

| 25-19-8 | 25 | 19 | 9 | 10.5 | 1.5 | ||||

| 27-21-8 | 27 | 21 | 9 | 10.5 | 1.5 | ||||

| 28-22-8 | 28 | 22 | 9 | 10.5 | 1.5 | ||||

| 30-22-10 | 30 | 22 | 12 | 13.5 | 1.5 | ||||

| 32-24-10 | 32 | 24 | 12 | 13.5 | 1.5 | ||||

| 35-27-10 | 35 | 27 | 12 | 13.5 | 1.5 | ||||

| 36-28-10 | 36 | 28 | 12 | 13.5 | 1.5 | ||||

| 40-32-10 | 40 | 32 | 12 | 13.5 | 1.5 | ||||

| 43-35-10 | 43 | 35 | 12 | 13.5 | 1.5 | ||||

| 45-37-10 | 45 | 37 | 12 | 13.5 | 1.5 | ||||

| 50-42-10 | 50 | 42 | 12 | 13.5 | 1.5 | ||||

| 55-43-14 | 55 | 43 | 16 | 18 | 2 | ||||

| 55-47-10 | 55 | 47 | 12 | 13.5 | 1.5 | ||||

| 56-44-14 | 56 | 44 | 16 | 18 | 2 | ||||

| 56-48-14 | 56 | 48 | 12 | 13.5 | 2 | ||||

| 60-48-14 | 60 | 48 | 16 | 18 | 2 | ||||

| 63-51-14 | 63 | 51 | 16 | 18 | 2 | ||||

| 65-53-14 | 65 | 53 | 16 | 18 | 2 | ||||

| 68-56-14 | 68 | 56 | 16 | 18 | 2 | ||||

| 70-58-14 | 70 | 58 | 16 | 18 | 2 | ||||

| 75-63-14 | 75 | 63 | 16 | 18 | 2 | ||||

| 78-66-14 | 78 | 66 | 16 | 18 | 2 | ||||

| 80-68-14 | 80 | 68 | 16 | 18 | 2 | ||||

| 85-73-14 | 85 | 73 | 16 | 18 | 2 | ||||

| 90-78-14 | 90 | 78 | 16 | 18 | 2 | ||||

| 95-83-14 | 95 | 83 | 16 | 18 | 2 | ||||

| Specification | Groove size | |||||

| DH9f8 | dh10 | HA | HB | T | ||

| 100-88-14 | 100 | 88 | 16 | 18 | 2 | |

| 105-89-18 | 105 | 89 | 20 | 22.5 | 2.5 | |

| 110-90-16 | 110 | 90 | 18 | 20 | 2 | |

| 110-94-18 | 110 | 94 | 20 | 22.5 | 2.5 | |

| 115-99-18 | 115 | 99 | 20 | 22.5 | 2.5 | |

| 120-104-18 | 120 | 104 | 20 | 22.5 | 2.5 | |

| 125-109-18 | 125 | 109 | 20 | 22.5 | 2.5 | |

| 127-111-18 | 127 | 111 | 20 | 22.5 | 2.5 | |

| 130-114-18 | 130 | 114 | 20 | 22.5 | 2.5 | |

| 135-119-18 | 135 | 119 | 20 | 22.5 | 2.5 | |

| 140-124-18 | 140 | 124 | 20 | 22.5 | 2.5 | |

| 145-129-18 | 145 | 129 | 20 | 22.5 | 2.5 | |

| 150-134-18 | 150 | 134 | 20 | 22.5 | 2.5 | |

| 155-139-18 | 155 | 139 | 20 | 22.5 | 2.5 | |

| 160-144-18 | 160 | 144 | 20 | 22.5 | 2.5 | |

| 165-149-18 | 165 | 149 | 20 | 22.5 | 2.5 | |

| 170-154-18 | 170 | 154 | 20 | 22.5 | 2.5 | |

| 175-159-18 | 175 | 159 | 20 | 22.5 | 2.5 | |

| 180-164-18 | 180 | 164 | 20 | 22.5 | 2.5 | |

| 185-169-18 | 185 | 169 | 20 | 22.5 | 2.5 | |

| 190-174-18 | 190 | 174 | 20 | 22.5 | 2.5 | |

| 195-179-18 | 195 | 179 | 20 | 22.5 | 2.5 | |

| 200-184-18 | 200 | 184 | 20 | 22.5 | 2.5 | |

| 210-194-18 | 210 | 194 | 20 | 22.5 | 2.5 | |

| 215-199-18 | 215 | 199 | 20 | 22.5 | 2.5 | |

| 220-204-18 | 220 | 204 | 20 | 22.5 | 2.5 | |

| 225-209-18 | 225 | 209 | 20 | 22.5 | 2.5 | |

| 230-214-18 | 230 | 214 | 20 | 22.5 | 2.5 | |

| 240-224-18 | 240 | 224 | 20 | 22.5 | 2.5 | |

| 245-229-18 | 245 | 229 | 20 | 22.5 | 2.5 | |

| 250-234-18 | 250 | 234 | 20 | 22.5 | 2.5 | |

| 255-239-18 | 255 | 139 | 20 | 22.5 | 2.5 | |

| 260-244-18 | 260 | 244 | 20 | 22.5 | 2.5 | |

| 265-249-18 | 265 | 249 | 20 | 22.5 | 2.5 | |

| Specification | Groove size | ||||

| DH9f8 | dh10 | HA | HB | T | |

| 270-254-18 | 270 | 254 | 20 | 22.5 | 2.5 |

| 280-264-18 | 280 | 267 | 20 | 22.5 | 2.5 |

| 285-269-18 | 285 | 269 | 20 | 22.5 | 2.5 |

| 290-274-18 | 290 | 274 | 20 | 22.5 | 2.5 |

| 300-284-18 | 300 | 284 | 20 | 22.5 | 2.5 |

| 310-286-24 | 310 | 286 | 26.5 | 30 | 3 |

| 310-290-21 | 310 | 290 | 22 | 25 | 3 |

| 325-301-24 | 325 | 301 | 26.5 | 30 | 3 |

| 320-296-24 | 320 | 296 | 26.5 | 30 | 3 |

| 330-306-24 | 330 | 306 | 26.5 | 30 | 3.5 |

| 340-316-24 | 340 | 316 | 26.5 | 30 | 3 |

| 350-326-24 | 350 | 326 | 26.5 | 30 | 3 |

| 360-336-24 | 360 | 336 | 26.5 | 30 | 3 |

| 365-341-24 | 365 | 341 | 26.5 | 30 | 3 |

| 366-342-24 | 366 | 342 | 26.5 | 30 | 3.5 |

| 370-346-24 | 370 | 346 | 26.5 | 30 | 3.5 |

| 380-356-24 | 380 | 356 | 26.5 | 30 | 3 |

| 390-366-24 | 390 | 366 | 26.5 | 30 | 3 |

| 400-376-24 | 400 | 376 | 26.5 | 30 | 3 |

| 420-396-24 | 420 | 396 | 26.5 | 30 | 3 |

| 430-406-24 | 430 | 406 | 26.5 | 30 | 3 |

| 440-416-24 | 440 | 416 | 26.5 | 30 | 3 |

| 450-426-24 | 450 | 426 | 26.5 | 30 | 3 |

| 460-436-24 | 460 | 436 | 26.5 | 30 | 3 |

| 470-446-24 | 470 | 446 | 26.5 | 30 | 3 |

| 480-456-24 | 480 | 456 | 26.5 | 30 | 3 |

| 500-476-24 | 500 | 476 | 26.5 | 30 | 4 |

| 520-496-24 | 520 | 496 | 26.5 | 30 | 4 |

| 530-487-24 | 530 | 487 | 26.5 | 30 | 4 |

| 530-506-24 | 530 | 506 | 26.5 | 30 | 4 |

| 540-516-24 | 540 | 516 | 26.5 | 30 | 4 |

| 550-526-24 | 550 | 526 | 26.5 | 30 | 3.5 |

| 560-536-24 | 560 | 536 | 26.5 | 30 | 4 |

| 570-546-24 | 570 | 546 | 26.5 | 30 | 4 |

| Specification | Groove size | ||||

| DH9f8 | dh10 | HA | HB | T | |

| 580-556-24 | 580 | 556 | 26.5 | 30 | 4 |

| 600-576-24 | 600 | 576 | 26.5 | 30 | 4 |

| 625-601-24 | 625 | 601 | 26.5 | 30 | 3.5 |

| 630-606-24 | 630 | 606 | 26.5 | 30 | 4 |

| 650-626-24 | 650 | 626 | 26.5 | 30 | 4 |

| 670-646-24 | 670 | 646 | 26.5 | 30 | 4 |

| 680-656-24 | 680 | 656 | 26.5 | 30 | 4 |

| 700-676-24 | 700 | 676 | 26.5 | 30 | 4 |

| 710-686-24 | 710 | 686 | 26.5 | 30 | 4 |

| 750-726-24 | 750 | 726 | 26.5 | 30 | 4 |

| 780-756-24 | 780 | 756 | 26.5 | 30 | 4 |

| 790-766-24 | 790 | 766 | 26.5 | 30 | 4 |

| 800-776-24 | 800 | 776 | 26.5 | 30 | 4 |

| 850-826-24 | 850 | 826 | 26.5 | 30 | 3.5 |

| 860-836-24 | 860 | 836 | 26.5 | 30 | 4 |

| 870-846-24 | 870 | 846 | 26.5 | 30 | 4 |

| 900-876-24 | 900 | 876 | 26.5 | 30 | 3.5 |

| 940-916-24 | 940 | 916 | 26.5 | 30 | 4 |

| 950-926-24 | 950 | 926 | 26.5 | 30 | 4 |

| 1000-976-24 | 1000 | 976 | 26.5 | 30 | 4 |

| 1200-1176-24 | 1200 | 1176 | 26.5 | 30 | 4 |

| 1600-1576-24 | 1600 | 1576 | 26.5 | 30 | 4 |

| *105-93-14 | 105 | 93 | 16 | 18 | 2 |

| *110-98-14 | 110 | 98 | 16 | 18 | 2 |

| *115-103-14 | 115 | 103 | 16 | 18 | 2 |

| *120-108-14 | 120 | 108 | 16 | 18 | 2 |

| *125-113-14 | 125 | 113 | 16 | 18 | 2 |

| *130-118-14 | 130 | 118 | 16 | 18 | 2 |

| *135-123-14 | 135 | 123 | 16 | 18 | 2 |

| *140-128-14 | 140 | 128 | 16 | 18 | 2 |

| *145-133-14 | 145 | 133 | 16 | 18 | 2 |

| *150-138-14 | 150 | 138 | 16 | 18 | 2 |

| *155-143-14 | 155 | 143 | 16 | 18 | 2 |

| *160-148-14 | 160 | 148 | 16 | 18 | 2 |

Please feel free to contact me.