PTB Custom Small Shaft Mini Size Spring Reinforced Seal

PTB Spring Reinforced Seal

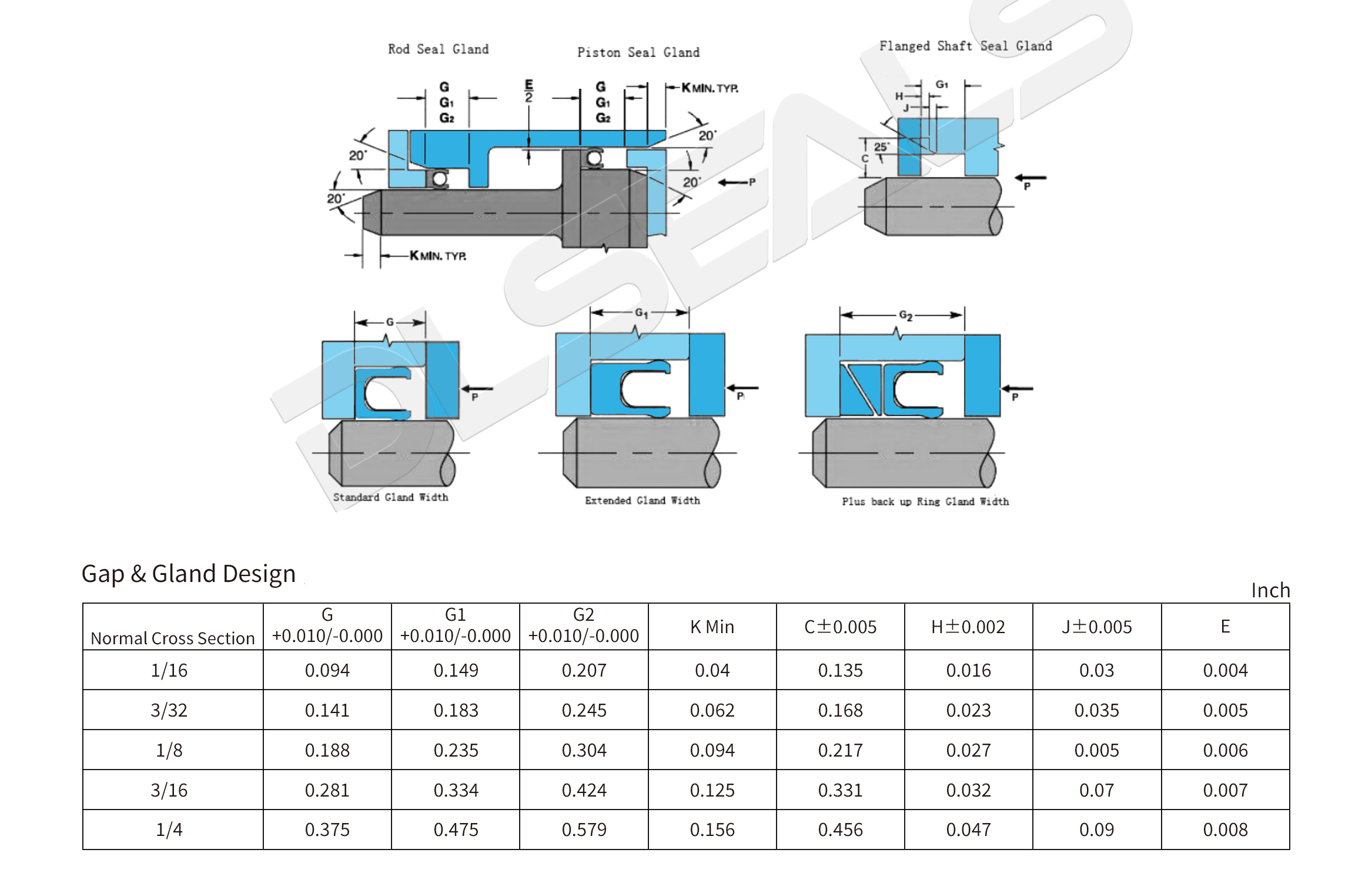

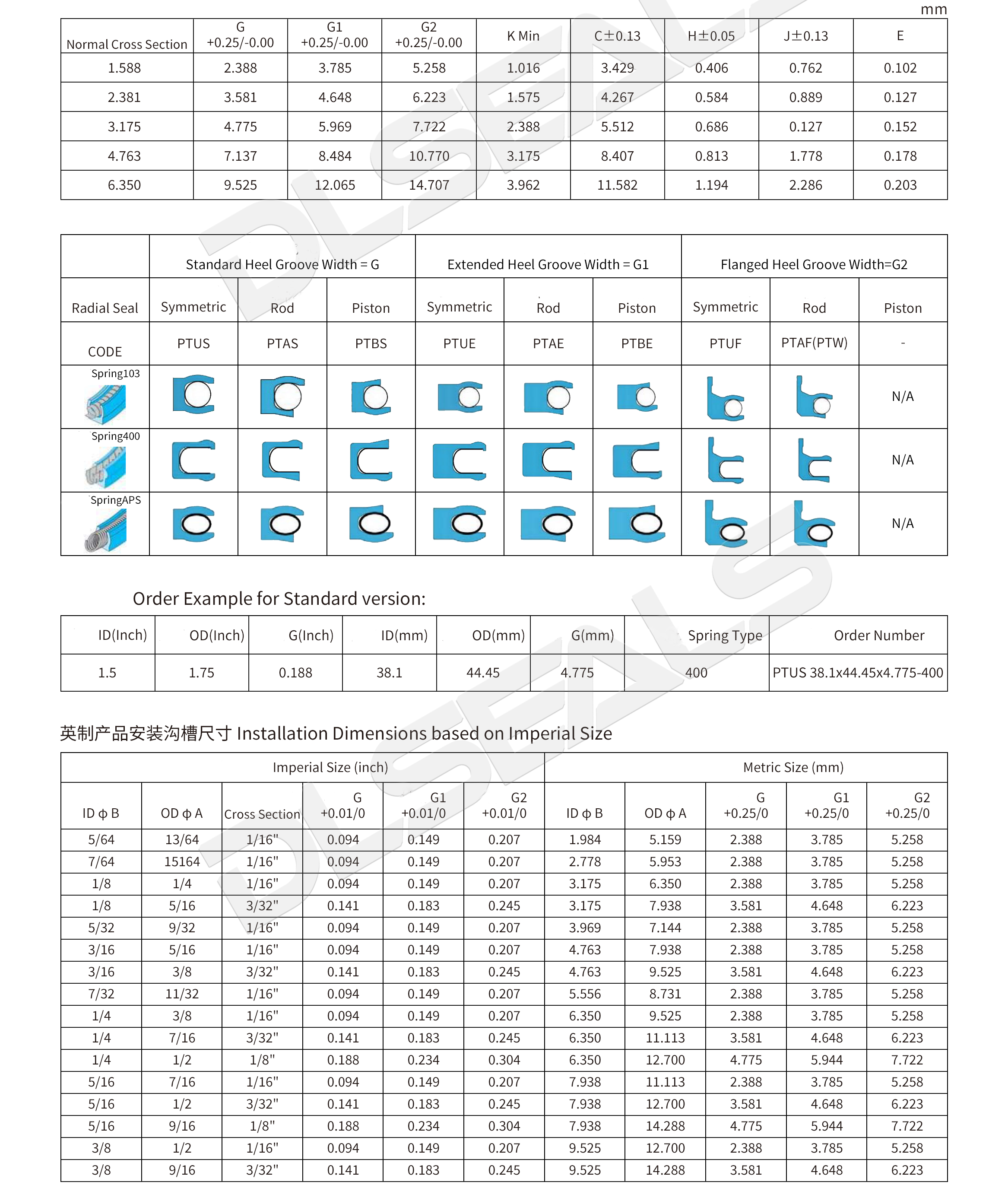

● While most of the DLSEALS Spring Energized PTFE seals canbe used as static radial seals, the DLSEALS 103 is generallyrecommended for this service.lt’s moderate to high spring load provides positive sealing under most staticsealing conditions.

Radial Seals in Reciprocating Motion

● The most common applications of DLSEALS Seals arereciprocating radial motion.For rod piston sealingand similar applications,the DLSEALS Seals 400 isrecommended for general purpose sealing at lowto moderate pressures.This series has a low load, high deflection spring that provides low friction sealing and long wear life, and compensates for minor hardware misalignment.The DLSEALS Seals APS uses a round wire spring energizer,which has the advantage of producing an almost constantspring load over a wide deflection range.This type of sealaccommodates variation in hardware dimensions (tolerances)and/or provides effective sealing loads over.

large seal wear allowance,Also it can be installed in verysmall coil, which makes it particularly suitable for smallseals and seals requiring low friction values. For more severe dynamic conditions,the DLSEALS Seals 103isrecommended.The higher spring load provides positives sealing with some increase in seal friction. articularly suitable for medium to high pressure service,the 103 is also an excellent rod seal for positive sealing.

The DLSEALS Seals 400 comes with durable spring and ruggedjacket,is an excellent choice for heavy-duty sealing applications and long wear life.

Radial Seals in Rotary Motion

✔ All of the DLSEALS Seals designs can be used in slow tomoderate speed rotary or oscillatory applications at lowPressure.In rotary shaft applications the flanged designPTW(PTAF) and PTUF is recommended.The flange is

clamped in the hardware to prevent the seal from rotatingwith the shaft.Rotation can occur with the standard designsdue to thermal and other effects.

✔ The flanged DLSEALS Seals APS and 400 are recommended formost rotary/oscillatory applications.The light spring loadminimizes friction at pressures under 0.1 MPa, with surfacespeeds in the range of 1-1.5 m./s.At higher pressures, reducedsurface speeds are required to prolong seal wear life.Theresilient U-shaped spring allows for minor shaft misalignment.For very slow speeds-under 0.25m/s and intermittent rotary/oscillatory motion at higher pressure, the flangedDLSEALS Seals 103 is recommended.

About Us

DLSEALS was founded in 1994 as a seal technology application solution provider, dedicated to providing one-stop seal development and manufacturing solutions to customers worldwide.

With experience in the seal industry for 29 years, DLSEALS is a reliable partner and resource-rich ,seal specialist who can help you solveseal supply or technical issues and mprove the reliability and performance of your equipment.

DLSEALS focuses on customer needs and is a reliable partner and supplier to customers in more than 110 countries worldwide, helping them solve supply and technical problems. We have our own technical center and testing facilities, a comprehensive laboratory that integrates product development, manufacturing and testing; with material formulation tests, physical testing tests, chemical tests, pilot production processes and product testing laboratories.

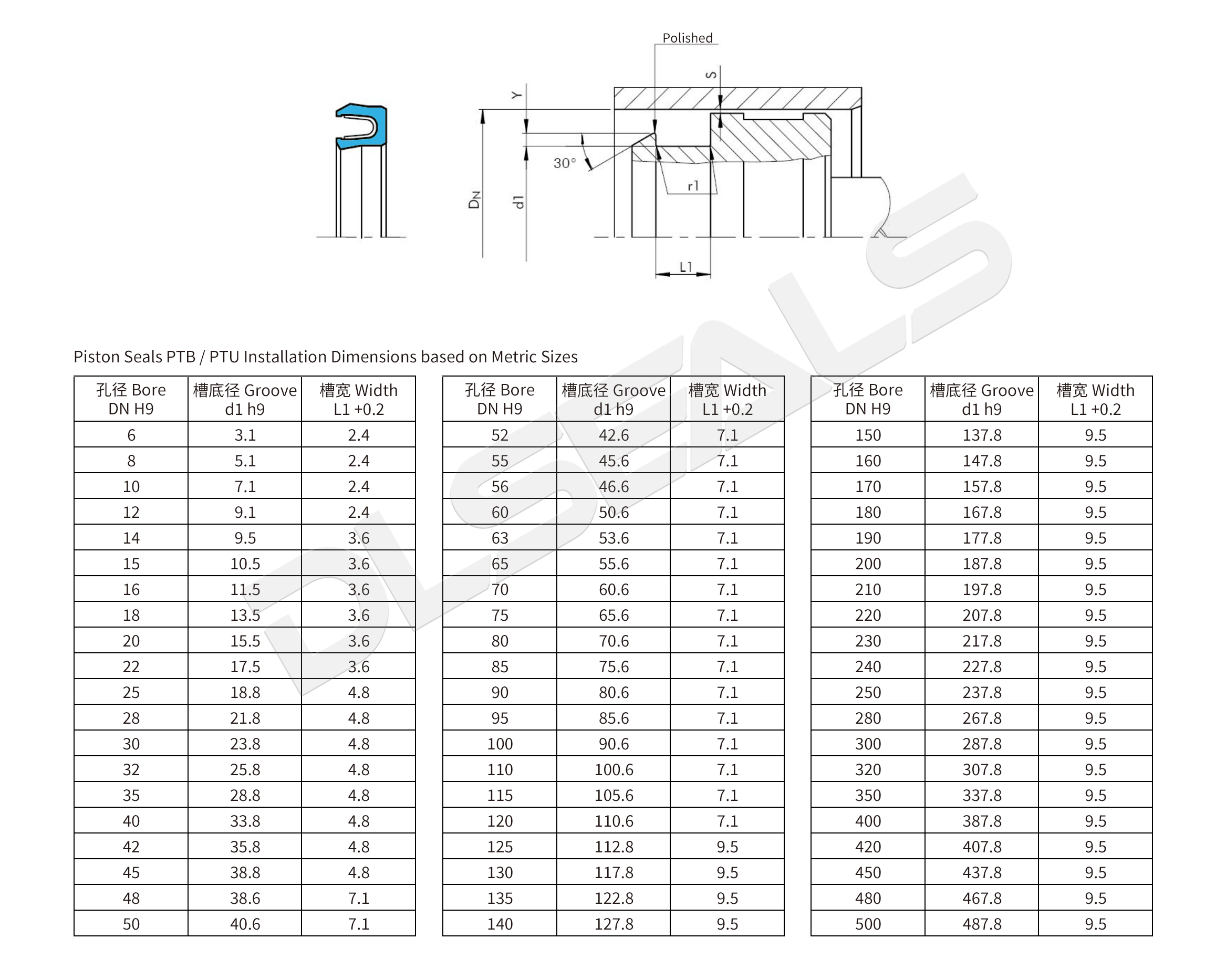

PTU/PTA/PTB