Axial Metal C-nooca Seal Giraanta Cimilada Cimilada ee birta

Sharaxaada Alaabta

"Axial birta nooca C-ganaanadda shaabadeynta waxay ku habboon tahay xiritaanka axial ee booska cylindrical ee u dhexeeya godka iyo shafka, giraanta xiritaanka waa faragelin ku habboon daloolka iyo shafka siday u kala horreeyaan, iyo jihada furitaanka ee nooca C-ga ayaa wajahaya dhexdhexaadiyaha dhinaca cadaadiska.

Ka dib markii la rakibo, giraanta C-qaabeeya waxay ku jirtaa xaalad qallafsan oo xad-dhaaf ah, iyo dabacsanaanta giraanta C-qaabeeya waxay ka dhigaysaa giraanta xirmada inay si dhow ula socoto godka iyo shafka;marka la shaqeynayo, cadaadiska dhexdhexaadka ah ayaa buuxinaya godka gudaha ee C-qaabeeya, taas oo ka dhigaysa giraanta xirmada, daloolka iyo shafka ayaa si aad ah ugu habboon.Si adag, si loo gaaro shaabad is-xajin.Giraantu waxay ku haboon tahay in lagu xidho cadaadis sare iyo mid hoose oo kala duwan iyo noocyada kala duwan ee warbaahinta, waxaana sidoo kale loo isticmaali karaa axially dhaqdhaqaaqa dhaqdhaqaaqa."

Iga (ama jir kale oo laastikada ah) ayaa ku dhex jira godka gudaha ee qaabka C, kaas oo u adkeysan kara cadaadis sare ama shoog iyo gariir xoog leh, oo leh isku halaynta daboolka oo xasilloon.

Tilmaamid

| Xir xulashada walxaha | Inconel718,Wax la beddeli karo | ||||||||

| Xulashada Qalabka Guga | 321,304,316,InconelX-750,Inconel718,GH605,NINONIC90..Wax la beddeli karo | ||||||||

| Dhexroorka qaybta * dhumucda gidaarka | Eeg shaxda xulashada, sifooyin gaar ah ayaa diyaar ah | ||||||||

| Doorashooyinka dahaarka dusha sare | Qalin, naxaas, nikkel, ama aan dahaadh lahayn | ||||||||

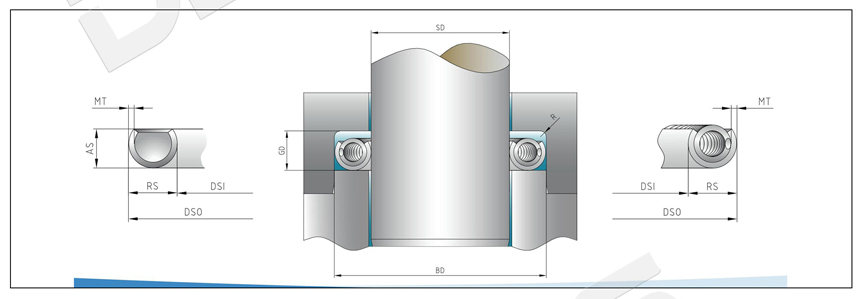

Axial Metal C-nooca Xulashada giraanta Seal

| SD | RS | MT | AS | DSO | DSl | BD | SD | |||

| 9-32 | 1.6 | 0.25 | 0.35 | 1.3 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0,+0.03) |

| 32-64 | 0.25 | 0.35 | BD+0.10 | ±0.03 | SD-0.10 | ±0.03 | (-0.03,0) | (0,+0.03) | ||

| 12-32 | 2.4 | 0.25 | 0.4 | 2.05 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0,+0.03) |

| 32-76 | 0.25 | 0.4 | BD+0.10 | ±0.03 | SD-0.10 | ±0.03 | (-0.03,0) | (0,+0.03) | ||

| 19-64 | 3.2 | 0.4 | 0.5 | 2.6 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0,+0.03) |

| 64-203 | 0.4 | 0.5 | BD+0.15 | ±0.05 | SD-0.15 | ±0.05 | (-0.05,0) | (0,+0.05) | ||

| 50-152 | 4 | 0.5 | 0.65 | 3.3 | BD+0.15 | ±0.05 | SD-0.15 | ±0.05 | (-0.05,0) | (0,+0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.18 | ±0.05 | SD-0.18 | ±0.05 | (-0.05,0) | (0,+0.05) | ||

| 76-152 | 4.8 | 0.5 | 0.65 | 4.1 | BD+0.18 | ±0.05 | SD-0.18 | ±0.05 | (-0.05,0) | (0,+0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.20 | ±0.06 | SD-0.20 | ±0.06 | (-0.05,0) | (0,+0.05) | ||

| 102-165 | 6.4 | 0.64 | 0.8 | 5.4 | BD+0.20 | ±0.06 | SD-0.20 | ±0.06 | (-0.05,0) | (0,+0.05) |

| 165-254 | 0.64 | 0.8 | BD+0.23 | ±0.06 | SD-0.23 | ±0.06 | (-0.05,0) | (0,+0.05) | ||

| 254-400 | 0.64 | 0.8 | BD+0.26 | ±0.08 | SD-0.26 | ±0.08 | (-0.05,0) | (0,+0.05) | ||

| 400-600 | 0.64 | 0.8 | BD+0.30 | ±0.10 | SD-0.30 | ±0.10 | (-0.05,0) | (0,+0.05) | ||