Spiral Wound Gasket For 0.750 Inch Flange 304 Winding Flexible Graphite

Product Description

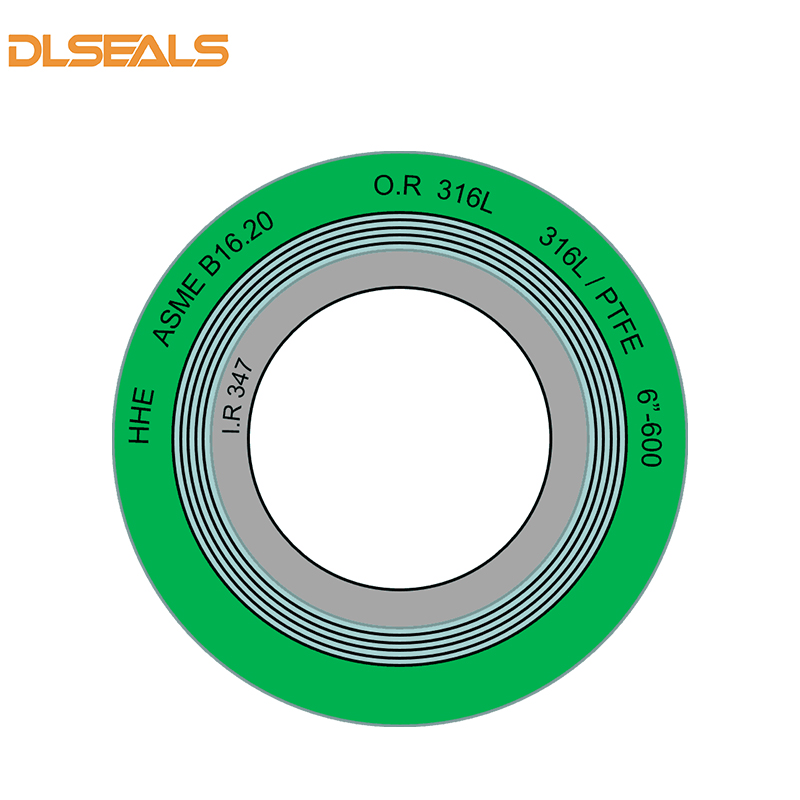

● Flange gaskets are divided into rubber gaskets, graphite gaskets, and metal spiral gaskets (basic type). They use standard and high-quality SS304, SS316 ("V" or "W" shape) metal belts and other alloy materials with graphite and PTFE. Other flexible materials are overlapped and spirally wound, and the metal band is fixed by spot welding at the beginning and the end. Its function is to play a sealing role in the middle of the two flanges.

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

Brand Name

|

DLSEALS

|

|

Model Number

|

Graphite Spiral Wound Gasket

|

|

The characteristics of

|

fire

|

|

Whether customization is supported

|

Supports OEM and ODM

|

|

The time of delivery

|

Available in stock or mould 7 days

|

|

Is it the source factory?

|

28 years of experience in sealing parts specialist factory

|

Performance

Performance: high temperature, high pressure, corrosion resistance, good compression rate and rebound rate.

Application: Sealing parts of pipes, valves, pumps, manholes, pressure vessels and heat exchange equipment at the joints of petroleum, chemical, electric power, metallurgy, shipbuilding, papermaking, medicine, etc. are ideal static sealing materials.

Stainless steel belt shape: "V" "W" "SUS" "U".

Stainless steel belt material: A3, 304, 304L, 316, 316L, Monel, titanium Ta.

Adaptation temperature: -196℃--+870℃ (flexible graphite)

≤ +250℃ (Polytetrafluoroethylene)

≤ +500℃ (other materials)

Medium: suitable for high temperature and high pressure steam, oil, oil and gas, solvent, hot coal body oil, etc.

Working pressure: ≤300Mpa

Maximum processing size: 2800 mm; special specifications or various non-standard products can be produced according to your requirements.

Minimum preload specific pressure: y=68 MPa