Axial Metal C-aina ya Seal Pete Spring Metal Weatherstripping

Maelezo ya bidhaa

"Pete ya kuziba ya axial ya chuma ya aina ya C inafaa kwa kuziba kwa axial ya nafasi ya silinda kati ya shimo na shimoni, pete ya kuziba ni ya kuingilia kati na shimo na shimoni kwa mtiririko huo, na mwelekeo wa ufunguzi wa aina ya C unakabiliwa na kati. upande wa shinikizo.

Baada ya ufungaji, pete ya umbo la C iko katika hali ya deformation ya elastic nyingi, na elasticity ya pete ya C hufanya pete ya kuziba inafaa kwa karibu na shimo na shimoni;wakati wa kufanya kazi, shinikizo la kati linajaza cavity ya ndani ya C, na kufanya pete ya kuziba, shimo na shimoni zinafaa kwa karibu zaidi.Tight, ili kufikia muhuri wa kujifunga.Pete ya kuziba inafaa kwa kuziba shinikizo la juu na la chini na aina tofauti za vyombo vya habari, na pia inaweza kutumika kwa kuziba kwa nguvu kwa axially."

Chemchemi (au mwili mwingine wa elastic) umeingizwa kwenye cavity ya ndani yenye umbo la C, ambayo inaweza kuhimili shinikizo la juu au mshtuko wenye nguvu na mtetemo, na ina uaminifu zaidi wa kuziba.

Vipimo

| Uchaguzi wa nyenzo za muhuri | Inconel718, Nyenzo zinazoweza kubinafsishwa | ||||||||

| Uchaguzi wa nyenzo za Spring | 321,304,316、InconelX-750、Inconel718,GH605,NINONIC90..Nyenzo zinazoweza kubinafsishwa | ||||||||

| Kipenyo cha sehemu * unene wa ukuta | Tazama jedwali la uteuzi, vipimo maalum vinapatikana | ||||||||

| Chaguzi za mipako ya uso | Fedha, shaba, nikeli, au isiyojazwa | ||||||||

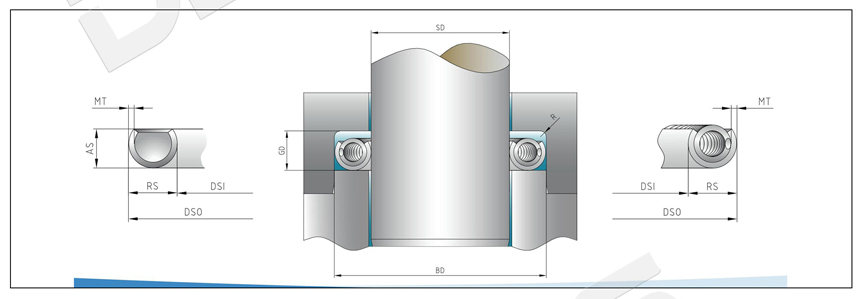

Jedwali la Uteuzi wa Pete ya Muhuri ya Axial Metal C

| SD | RS | MT | AS | DSO | DSl | BD | SD | |||

| 9-32 | 1.6 | 0.25 | 0.35 | 1.3 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0, +0.03) |

| 32-64 | 0.25 | 0.35 | BD+0.10 | ±0.03 | SD-0.10 | ±0.03 | (-0.03,0) | (0, +0.03) | ||

| 12-32 | 2.4 | 0.25 | 0.4 | 2.05 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0, +0.03) |

| 32-76 | 0.25 | 0.4 | BD+0.10 | ±0.03 | SD-0.10 | ±0.03 | (-0.03,0) | (0, +0.03) | ||

| 19-64 | 3.2 | 0.4 | 0.5 | 2.6 | BD+0.08 | ±0.03 | SD-0.08 | ±0.03 | (-0.03,0) | (0, +0.03) |

| 64-203 | 0.4 | 0.5 | BD+0.15 | ±0.05 | SD-0.15 | ±0.05 | (-0.05,0) | (0, +0.05) | ||

| 50-152 | 4 | 0.5 | 0.65 | 3.3 | BD+0.15 | ±0.05 | SD-0.15 | ±0.05 | (-0.05,0) | (0, +0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.18 | ±0.05 | SD-0.18 | ±0.05 | (-0.05,0) | (0, +0.05) | ||

| 76-152 | 4.8 | 0.5 | 0.65 | 4.1 | BD+0.18 | ±0.05 | SD-0.18 | ±0.05 | (-0.05,0) | (0, +0.05) |

| 152-254 | 0.5 | 0.65 | BD+0.20 | ±0.06 | SD-0.20 | ±0.06 | (-0.05,0) | (0, +0.05) | ||

| 102-165 | 6.4 | 0.64 | 0.8 | 5.4 | BD+0.20 | ±0.06 | SD-0.20 | ±0.06 | (-0.05,0) | (0, +0.05) |

| 165-254 | 0.64 | 0.8 | BD+0.23 | ±0.06 | SD-0.23 | ±0.06 | (-0.05,0) | (0, +0.05) | ||

| 254-400 | 0.64 | 0.8 | BD+0.26 | ±0.08 | SD-0.26 | ±0.08 | (-0.05,0) | (0, +0.05) | ||

| 400-600 | 0.64 | 0.8 | BD+0.30 | ±0.10 | SD-0.30 | ±0.10 | (-0.05,0) | (0, +0.05) | ||