U1 Piston Seal Hydraulic oils (mineral oil-based)

♠Description-U1 Piston Seal

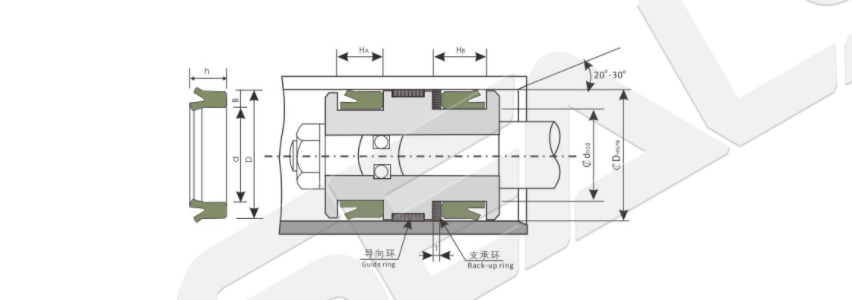

U1 Piston Seal is a kind of lip seal used for installing piston in the groove. The material used is imported CPU. Other PU ratio on the market of this product, the main advantages are heat resistance, small compression deformation, wear resistance, easy to install, adapt to harsh working conditions.

Application Range

| Pressure [MPa] | Temperature [℃] | Sliding speed[m/s] | Medium | |||||||||||||||

| Standard | 40 | -35...+100 | 0.5 | Hydraulic oils (mineral oil-based) | ||||||||||||||

♣Advantage

● Particularly strong wear resistance.

● Insensitivity to shock loads and pressure peaks.

● High crush resistance.

● It has an ideal sealing effect under no load and low-temperature conditions.

● Suitable for demanding working conditions.

● Easy to install.

Material

| Standard Design | PU | ||||||

| Special (on request) | FKM | ||||||

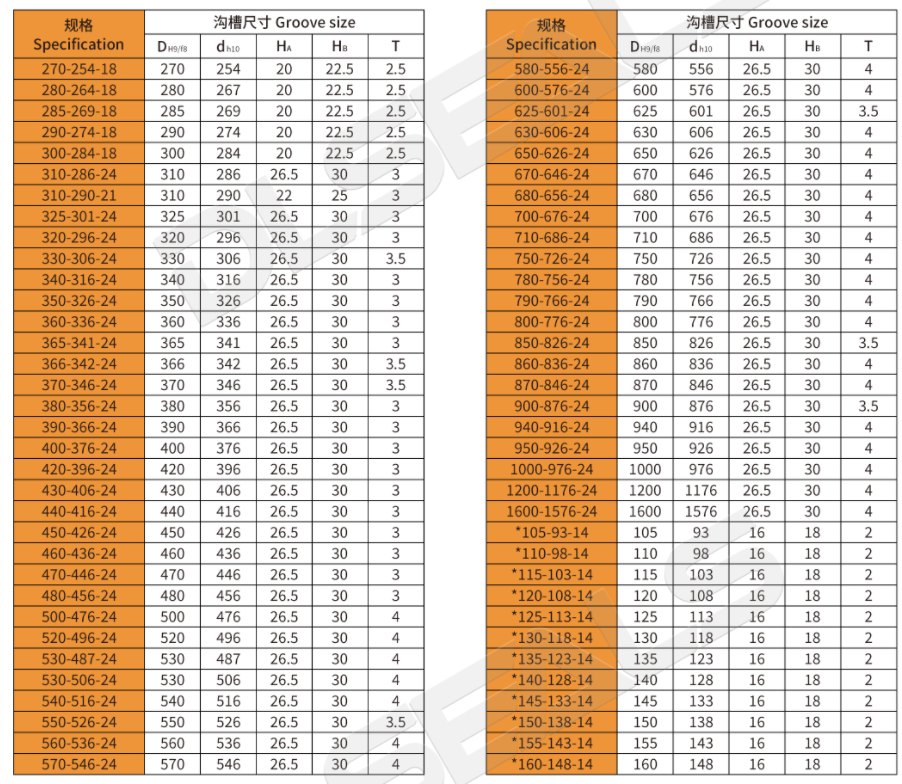

Size and Groove Dimensions U1

| Specification | Groove size | ||||||||

| DH₉/f₈ | dhio | Ha | HB | T | |||||

| 11-5-8 | 11 | 5 | 9 | 10.5 | 1.5 | ||||

| 12-6-8 | 12 | 6 | 9 | 10.5 | 1.5 | ||||

| 14-8-8 | 14 | 8 | 9 | 10.5 | 1.5 | ||||

| 16-10-8 | 16 | 10 | 9 | 10.5 | 1.5 | ||||

| 18-12-8 | 18 | 12 | 9 | 10.5 | 1.5 | ||||

| 20-14-8 | 20 | 14 | 9 | 10.5 | 1.5 | ||||

| 22-16-8 | 22 | 16 | 9 | 10.5 | 1.5 | ||||

| 24-18-8 | 24 | 18 | 9 | 10.5 | 1.5 | ||||

| 25-19-8 | 25 | 19 | 9 | 10.5 | 1.5 | ||||

| 27-21-8 | 27 | 21 | 9 | 10.5 | 1.5 | ||||

| 28-22-8 | 28 | 22 | 9 | 10.5 | 1.5 | ||||

| 30-22-10 | 30 | 22 | 12 | 13.5 | 1.5 | ||||

| 32-24-10 | 32 | 24 | 12 | 13.5 | 1.5 | ||||

| 35-27-10 | 35 | 27 | 12 | 13.5 | 1.5 | ||||

| 36-28-10 | 36 | 28 | 12 | 13.5 | 1.5 | ||||

| 40-32-10 | 40 | 32 | 12 | 13.5 | 1.5 | ||||

| 43-35-10 | 43 | 35 | 12 | 13.5 | 1.5 | ||||

| 45-37-10 | 45 | 37 | 12 | 13.5 | 1.5 | ||||

| 50-42-10 | 50 | 42 | 12 | 13.5 | 1.5 | ||||

| 55-43-14 | 55 | 43 | 16 | 18 | 2 | ||||

| 55-47-10 | 55 | 47 | 12 | 13.5 | 1.5 | ||||

| 56-44-14 | 56 | 44 | 16 | 18 | 2 | ||||

| 56-48-14 | 56 | 48 | 12 | 13.5 | 2 | ||||

| 60-48-14 | 60 | 48 | 16 | 18 | 2 | ||||

| 63-51-14 | 63 | 51 | 16 | 18 | 2 | ||||

| 65-53-14 | 65 | 53 | 16 | 18 | 2 | ||||

| 68-56-14 | 68 | 56 | 16 | 18 | 2 | ||||

| 70-58-14 | 70 | 58 | 16 | 18 | 2 | ||||

| 75-63-14 | 75 | 63 | 16 | 18 | 2 | ||||

| 78-66-14 | 78 | 66 | 16 | 18 | 2 | ||||

| 80-68-14 | 80 | 68 | 16 | 18 | 2 | ||||

| 85-73-14 | 85 | 73 | 16 | 18 | 2 | ||||

| 90-78-14 | 90 | 78 | 16 | 18 | 2 | ||||

| 95-83-14 | 95 | 83 | 16 | 18 | 2 | ||||

| Specification | Groove size | |||||

| DH₉/f₈ | dhio | HA | HB | T | ||

| 100-88-14 | 100 | 88 | 16 | 18 | 2 | |

| 105-89-18 | 105 | 89 | 20 | 22.5 | 2.5 | |

| 110-90-16 | 110 | 90 | 18 | 20 | 2 | |

| 110-94-18 | 110 | 94 | 20 | 22.5 | 2.5 | |

| 115-99-18 | 115 | 99 | 20 | 22.5 | 2.5 | |

| 120-104-18 | 120 | 104 | 20 | 22.5 | 2.5 | |

| 125-109-18 | 125 | 109 | 20 | 22.5 | 2.5 | |

| 127-111-18 | 127 | 111 | 20 | 22.5 | 2.5 | |

| 130-114-18 | 130 | 114 | 20 | 22.5 | 2.5 | |

| 135-119-18 | 135 | 119 | 20 | 22.5 | 2.5 | |

| 140-124-18 | 140 | 124 | 20 | 22.5 | 2.5 | |

| 145-129-18 | 145 | 129 | 20 | 22.5 | 2.5 | |

| 150-134-18 | 150 | 134 | 20 | 22.5 | 2.5 | |

| 155-139-18 | 155 | 139 | 20 | 22.5 | 2.5 | |

| 160-144-18 | 160 | 144 | 20 | 22.5 | 2.5 | |

| 165-149-18 | 165 | 149 | 20 | 22.5 | 2.5 | |

| 170-154-18 | 170 | 154 | 20 | 22.5 | 2.5 | |

| 175-159-18 | 175 | 159 | 20 | 22.5 | 2.5 | |

| 180-164-18 | 180 | 164 | 20 | 22.5 | 2.5 | |

| 185-169-18 | 185 | 169 | 20 | 22.5 | 2.5 | |

| 190-174-18 | 190 | 174 | 20 | 22.5 | 2.5 | |

| 195-179-18 | 195 | 179 | 20 | 22.5 | 2.5 | |

| 200-184-18 | 200 | 184 | 20 | 22.5 | 2.5 | |

| 210-194-18 | 210 | 194 | 20 | 22.5 | 2.5 | |

| 215-199-18 | 215 | 199 | 20 | 22.5 | 2.5 | |

| 220-204-18 | 220 | 204 | 20 | 22.5 | 2.5 | |

| 225-209-18 | 225 | 209 | 20 | 22.5 | 2.5 | |

| 230-214-18 | 230 | 214 | 20 | 22.5 | 2.5 | |

| 240-224-18 | 240 | 224 | 20 | 22.5 | 2.5 | |

| 245-229-18 | 245 | 229 | 20 | 22.5 | 2.5 | |

| 250-234-18 | 250 | 234 | 20 | 22.5 | 2.5 | |

| 255-239-18 | 255 | 139 | 20 | 22.5 | 2.5 | |

| 260-244-18 | 260 | 244 | 20 | 22.5 | 2.5 | |

| 265-249-18 | 265 | 249 | 20 | 22.5 | 2.5 | |

Write your message here and send it to us