JA o'chiruvchi muhr gidravlik silindrli o'chirish muhri

♠Ta'rif-JA o'chirish muhri

JA Wiper Seal chang, axloqsizlik, qum yoki mayda moddalarning kirib kelishini oldini oladi.Bunga hidoyat qismlarini katta darajada himoya qiladigan va muhrlarning ishlash muddatini uzaytiradigan maxsus dizayn bilan erishish mumkin.Bunga qo'shimcha ravishda, JA o'chirish moslamasining o'rnatilishi halqali vintlardek yoki qavslarni talab qilmaydi.Talabda qat'iy toleranslar va metall qo'shimchalar yo'q.Oʻchirish halqasi uzluksiz halqa boʻlib, truba ichiga oʻrnatish juda oson.Shunday qilib, chang halqasining orqa tomoni bosimdan himoyalangan bo'lishi kerak.

Qo'llash diapazoni

| Bosim[MPa | Harorat [℃] | Sirpanish tezligi[m/s] | O'rta | ||||

| Standart | -35...+100 | 1 | Gidravlik moylar (mineral moylarga asoslangan) | ||||

♣ Afzallik

Aşınma halqasi muhri gidravlik silindrning piston va piston rodi uchun yo'l-yo'riq va yordam beradi.Shuningdek, lateral yuklarni yutish.Shu bilan birga, silindrning harakatlanuvchi qismlari o'rtasidagi metall aloqani oldini olish va muhrlash tizimining ishlashini optimallashtirishi mumkin.

Yuvish moslamasi, qistirma - bu siqilish paytida birlashtirilgan ob'ektlardan yoki ichiga oqishning oldini olish uchun ikki yoki undan ortiq juft yuzalar orasidagi bo'shliqni to'ldiradigan mexanik muhr.

Yuqori bosimli bug 'tizimlari kabi maxsus ilovalar uchun qistirmalari asbestni o'z ichiga olishi mumkin.Biroq, asbest ta'siri bilan bog'liq sog'liq uchun xavfli bo'lganligi sababli, amaliy bo'lsa, biz asbest bo'lmagan qistirmali materiallardan foydalanamiz.

Material

| Standart | PU | |||||

| Maxsus (so'rov bo'yicha) | FKM | |||||

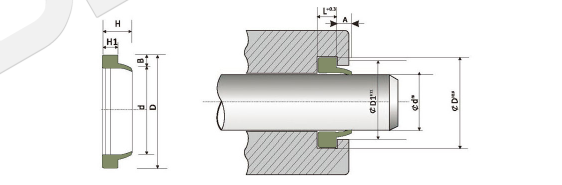

Spetsifikatsiya

| Spetsifikatsiya | Chuqur o'lchami | ||||||

| Df8 | DH10 | D1H11 | L+03 | A | |||

| 14-22.5-4/7 | 14 | 22.5 | 19 | 4 | 3 | ||

| 16-24-5/9 | 16 | 24 | 21 | 5 | 3 | ||

| 16-24.5-4/7 | 16 | 24.5 | 21 | 4 | 3 | ||

| 18-28-5/9 | 18 | 28 | 23 | 5 | 3 | ||

| 18-28,5-5/9 | 18 | 28.5 | 23 | 5 | 3 | ||

| 20-30-5/9 | 20 | 30 | 25 | 5 | 3 | ||

| 20-30,5-5/9 | 20 | 30.5 | 25 | 5 | 3 | ||

| 22-30-5/9 | 22 | 30 | 27 | S | 3 | ||

| 22-32-5/9 | 22 | 32 | 27 | 5 | 3 | ||

| 22-32-5/8.5 | 22 | 32 | 27 | 5 | 3 | ||

| 22-32.25-5/9 | 22 | 32.5 | 27 | 5 | 3 | ||

| 25-34-5/9 | 25 | 34 | 30 | 5 | 3 | ||

| 25-35-5/9 | 25 | 35 | 30 | 5 | 3 | ||

| 25-35,5-5/9 | 25 | 35.5 | 30 | 5 | 3 | ||

| 28-38-5/9 | 28 | 38 | 33 | S | 3 | ||

| 28-38,5-5/9 | 28 | 38.5 | 33 | 5 | 3 | ||

| 30-40-6/10 | 30 | 40 | 36 | 6 | 3 | ||

| 30-40,5-6/10 | 30 | 40.5 | 36 | 6 | 3 | ||

| 32-42-6/10 | 32 | 42 | 38 | 6 | 3 | ||

| 32-42,5-6/10 | 32 | 42.5 | 38 | 6 | 3 | ||

| 35-45-6/10 | 35 | 45 | 41 | 6 | 3 | ||

| 35-45,5-6/10 | 35 | 45.5 | 41 | 6 | 3 | ||

| 36-46,5-6/10 | 36 | 46.5 | 42 | 6 | 3 | ||

| 40-50-6/10 | 40 | 50 | 46 | 6 | 3 | ||

| 40-50,5-6/10 | 40 | 50.5 | 46 | 6 | 3 | ||

| 45-55-6/10 | 45 | 55 | 51 | 6 | 3 | ||

| 45-55,5-6/10 | 45 | 55.5 | 51 | 6 | 3 | ||

| 48-58,5-6/10 | 48 | 58.5 | 54 | 6 | 3 | ||

| 50-60-6/10 | 50 | 60 | 56 | 6 | 3 | ||

| 50-60,5-6/10 | 50 | 60.5 | 56 | 6 | 3 | ||

| 55-65-6/10 | 55 | 65 | 61 | 6 | 3 | ||

| 55-67-7/11 | 55 | 67 | 61 | 7 | 3.5 | ||

| 55-67,5-7/11 | 55 | 67.5 | 61 | 7 | 3.5 | ||

| 56-68.5-7/11 | 56 | 68.5 | 62 | 7 | 3.5 | ||

| 60-72-7/11 | 60 | 72 | 66 | 7 | 3.5 | ||

| 60-72,5-7/11 | 60 | 72.5 | 66 | 7 | 3.5 | ||

| 63-75-7/11 | 63 | 75 | 69 | 7 | 3.5 | ||

| 63-75,5-7/11 | 63 | 75.5 | 69 | 7 | 3.5 | ||

| 65-77-7/11 | 65 | 77 | 71 | 7 | 3.5 | ||

| 65-77,5-7/11 | 65 | 77.5 | 71 | 7 | 3.5 | ||

| 70-82-7/11 | 70 | 82 | 76 | 7 | 3.5 | ||

| 70-82,5-7/11 | 70 | 82.5 | 76 | 7 | 3.5 | ||

| 71-83,5-7/11 | 71 | 83.5 | 77 | 7 | 3.5 | ||

| 72-84,5-7/11 | 72 | 84.5 | 78 | 7 | 3.5 | ||

| 73-85-7/11 | 73 | 8s | 79 | 7 | 3.5 | ||

| 75-87-7/11 | 75 | 87 | 81 | 7 | 3.5 | ||

| 75-87,5-7/11 | 75 | 87.5 | 81 | 7 | 3.5 | ||