Ingcindezi yangaphakathi yensimbi yokuvala indandatho ye-E (i-E-type yangaphakathi yokuvula)

Incazelo Yomkhiqizo

Izigxivizo ze-Metal E-ring ziyingxenye ebalulekile yezinjini futhi zisetshenziswa kakhulu kwi-aerospace, i-steam turbine kanye nezimboni zezimoto.

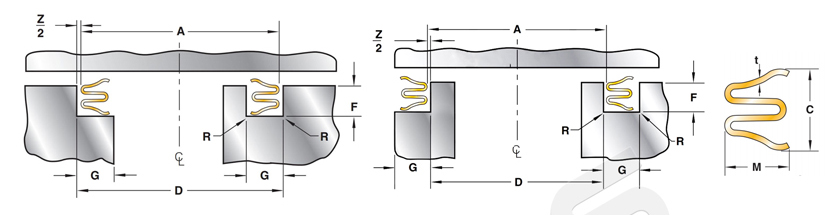

Uma kuqhathaniswa nezindandatho zokuvala ezimise okwe-O, ezimise okwe-C, ezimise okwe-U nezinye, izinzuzo zayo zisemthwalweni omncane wokucindezelwa odingekayo ukuze ufakwe, ukuqina okuhle (okuseduze no-100% ukuphindaphinda ekamelweni lokushisa), futhi ingasetshenziswa ngaphansi izinga lokushisa eliphezulu, ukucindezela okukhulu nokudlidliza. Isetshenziswa endaweni yokusebenza. Ngesikhathi sokusetshenziswa, ukuvulwa kwangaphakathi kohlobo lwe-E kulungele izimo zengcindezi yangaphakathi, futhi ukuvulwa kwangaphandle kohlobo lwe-E kulungele izimo zengcindezi yangaphandle. "Ingcindezi yesistimu. kwandisa ukunamathela phakathi kwendawo yokuvala kanye ne-flange (umsebenzi wokuzibamba), ngaleyo ndlela kunciphisa kakhulu izinga lokuvuza.

Ukucaciswa

| Ukukhetha izinto ezibonakalayo | I-Incone[X-750,Inconel718, into engenziwa ngendlela oyifisayo | |||||||||||||||||||

| Ububanzi besigaba * ukujiya kodonga | Bheka ithebula lokukhetha, imininingwane eyenziwe ngezifiso iyatholakala | |||||||||||||||||||

| Izinketho zokumboza ubuso | Igolide, isiliva, ithusi, i-nickel, ithini, i-PTFE, noma akukho plating | |||||||||||||||||||

I-EA1 ingcindezi yangaphakathi yensimbi E-ring

I-EA2 ingcindezi yangaphandle yensimbi E-ring

Ithebula Lokukhetha le-EA1

| Ibanga le-OD/ID | Ukuphakama okuzisholo | Ukujula kweGroove F | Ukubekezelelana | Ububanzi be-Groove G | Ubude bendandatho ye-E C | Ukubekezelelana | Ubukhulu bendandatho t | Usayizi wendandatho ka-M | ||||||||||||

| 45-205 | 1.6 | 1.60 | ±0.02 | 2.30 | 1.90 | ±0.08 | 0.15 | 1.70 | ||||||||||||

| 50-305 | 2.4 | 2.20 | ±0.03 | 2.90 | 2.60 | ±0.13 | 0.30 | 2.30 | ||||||||||||

| 50-305 | 2.4 | 2.20 | ±0.03 | 4.30 | 2.75 | ±0.13 | 0.30 | 3.70 | ||||||||||||

| 50-600 | 3.2 | 3.0 | ±0.05 | 4.20 | 3.35 | ±0.13 | 0.40 | 3.10 | ||||||||||||

| 85-915 | 4.80 | 4.6 | ±0.05 | 5.85 | 5.55 | ±0.15 | 0.40 | 4.80 | ||||||||||||

| 150-1220 | 6.40 | 6.28 | ±0.07 | 8.0 | 7.50 | ±0.18 | 0.50 | 6.80 | ||||||||||||